- +86-371-55909782 sales.eng@rezzgrind.com

- #3, LongCheng Square, #168 North Wenhua Road, Huiji District,Zhengzhou, Henan, China,450000

- Pon - Sob 8.00 - 18.00 Niedziela Zamknięte

Wszystkie kategorie

- odrywacze

- Związki

- Części robocze do strzałowania

- Materiały do szlifowania

- Metoda szlifowania

- maszyny szlifierskie

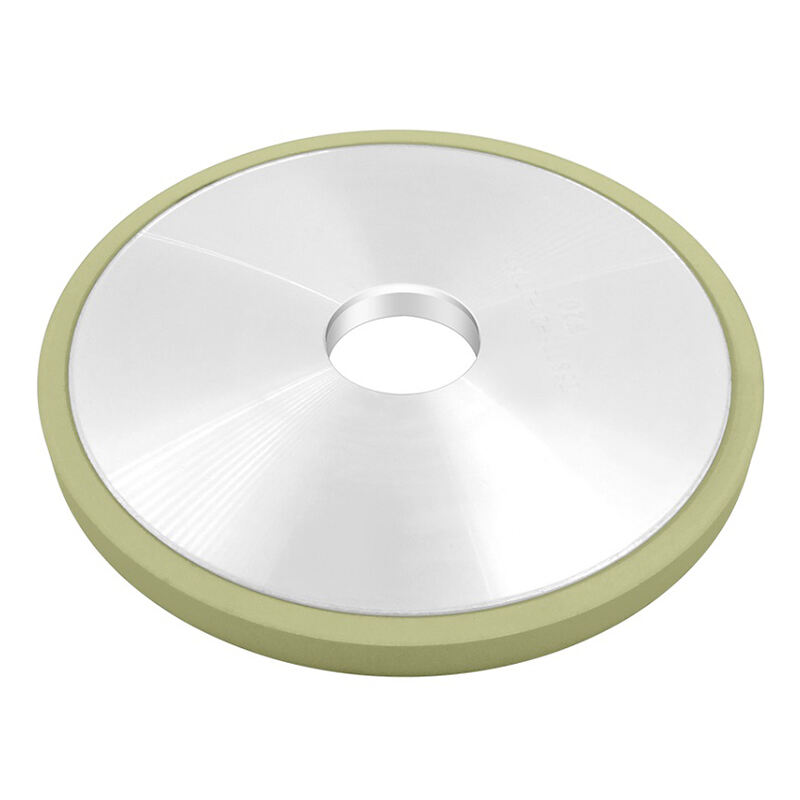

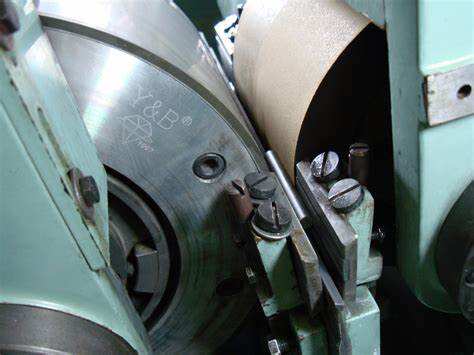

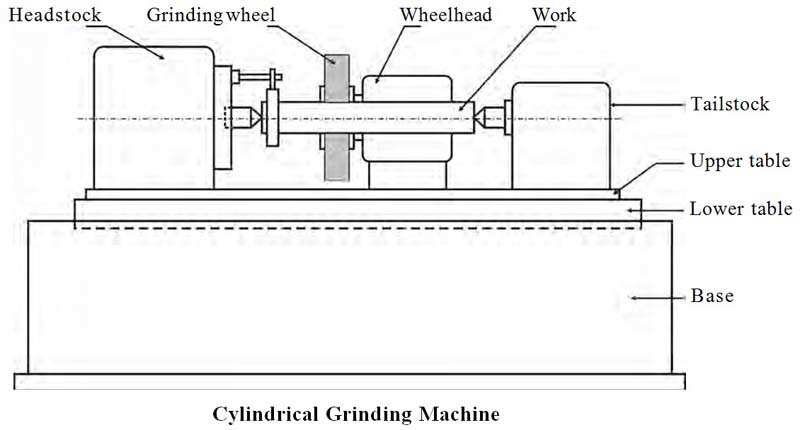

Koła do szlifowania maszyn cylindrycznych

Koła szlifujące walcowe są stosowane na maszynach szlifujących walcowych. RZ oferuje Koła Szlifujące Walcowe z różnymi abrazywami. Dostępne są Koła Szlifujące Tlenku Aluminiowego, Karbiku Krzemnego, Diamentowego i CBN.

Opis:

Szliфfowanie walcowe (nazywane również szlifowaniem z centrami) służy do szlifowania powierzchni walcowych i ramion wyrobku.

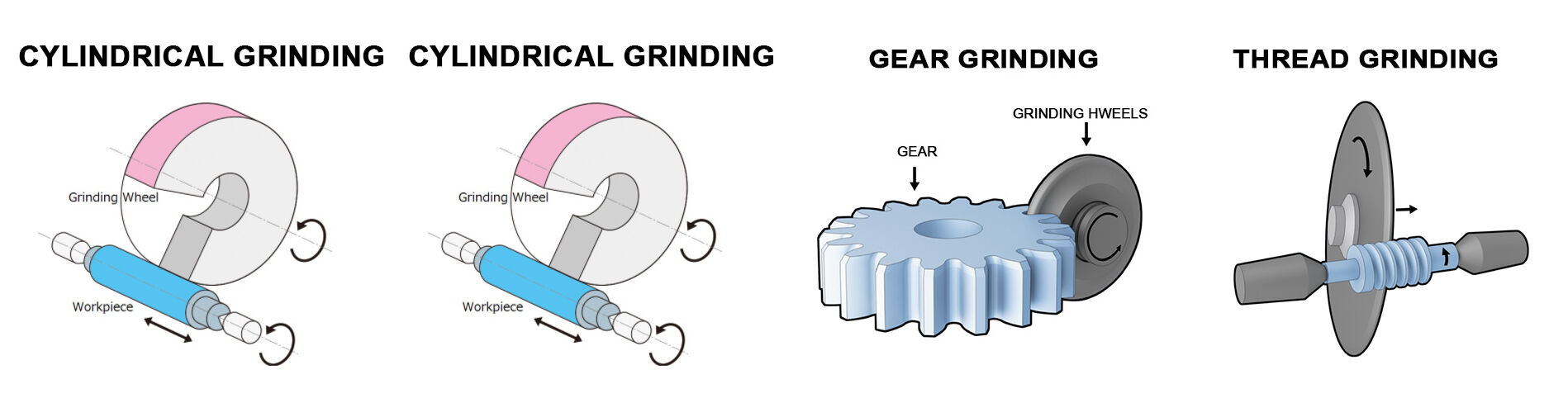

Istnieje pięć różnych rodzajów szlifowania walcowego (różne metody szlifowania obejmują prosty waleczkowy, stożkowy, powierzchnię końcową i całkowite szlifowanie kształtu):

* Szlifowanie zewnętrznej średnicy (OD)

* Szlifowanie wewnętrznej średnicy (ID)

* Szlifowanie poprzeczne

* Szlifowanie z podajnikiem pełzającym

* Szlifowanie bezśrodkowe

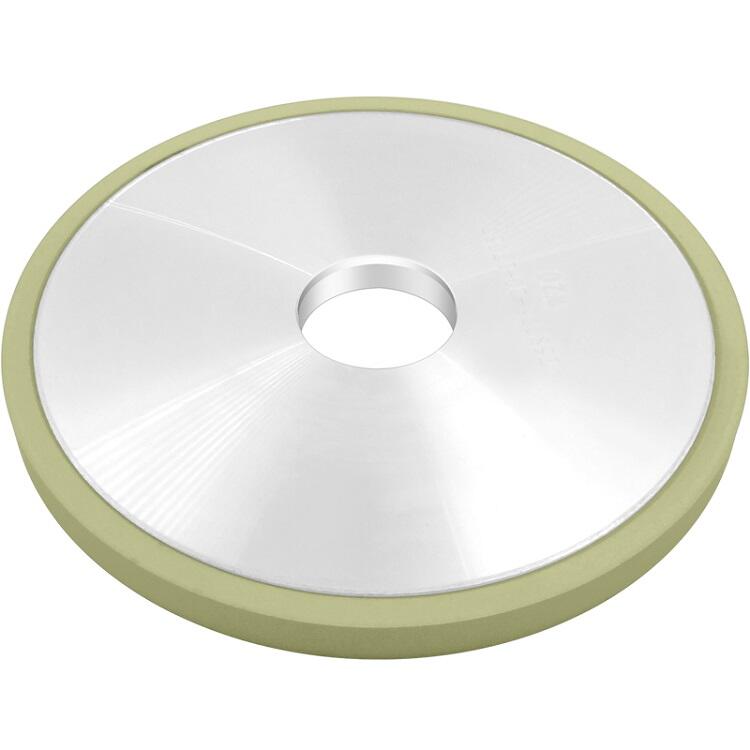

Diamentowe i CBN Kolka Do Szlifowania Walcowego

Diamentowe koło do szlifowania walcowego dla warstw termospryskowych

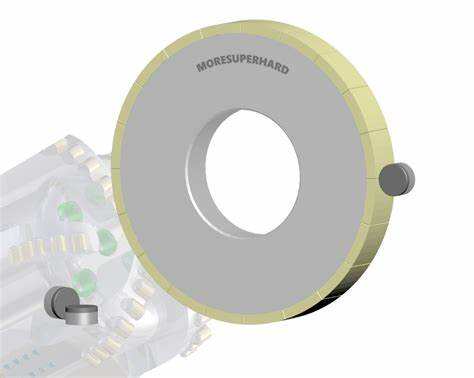

Bezśrodkowe koło szlifujące z diamentem

Walcowe koło diamentowe do noża PDC

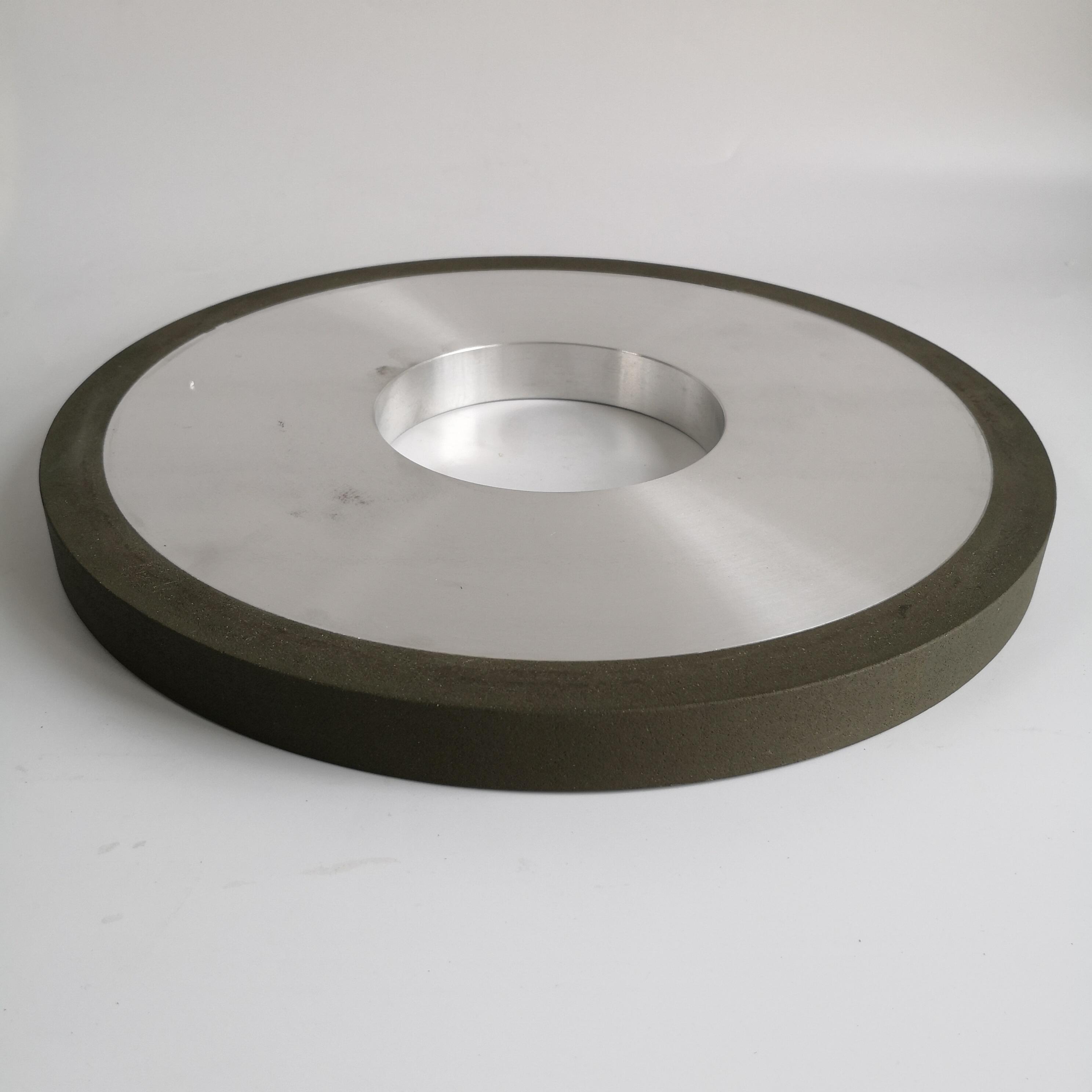

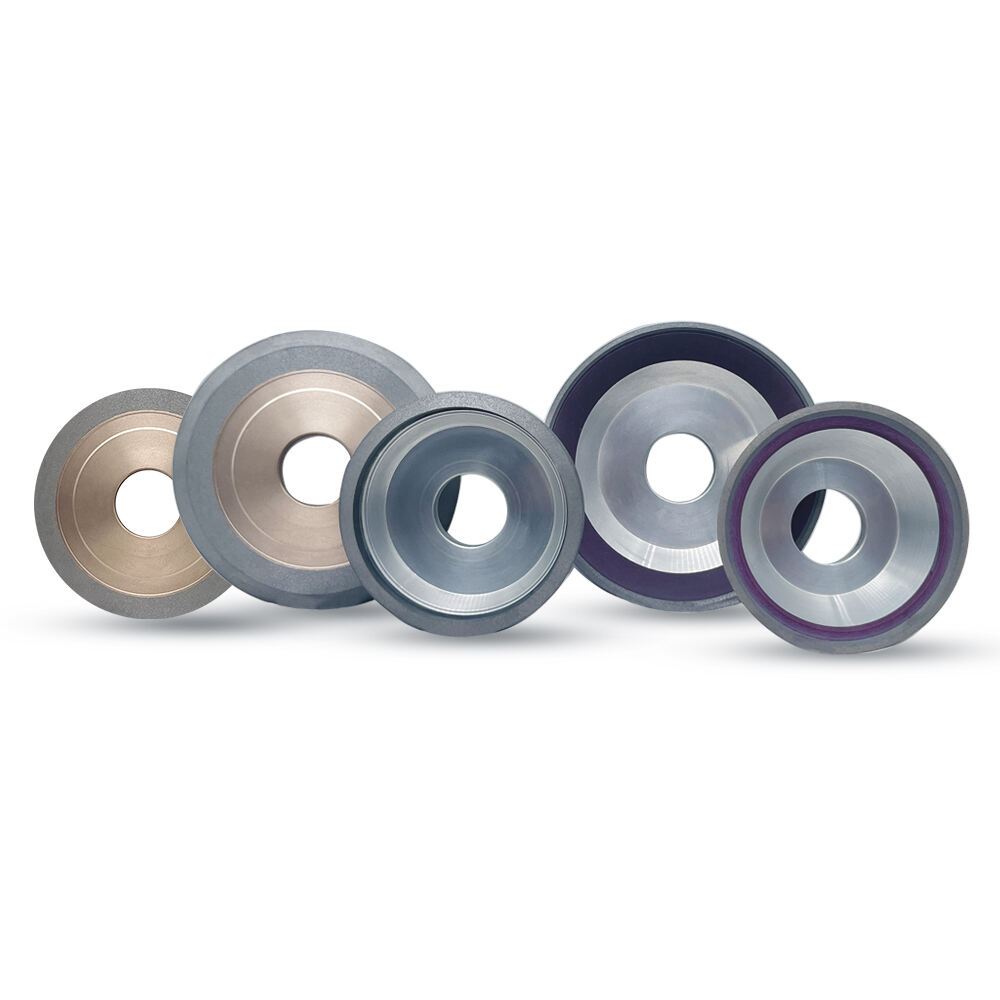

Ocierne Koła Szlifujące

Większość zastosowań wykorzystuje koła szlifujące z tlenkiem aluminium w wiązce witryfikowanej, przy czym rozmiary cząstek wahają się między 54 a 180, a stopnie twardości między H a L (w zależności od wymagań). Pozwala to osiągnąć optymalny balans między zużyciem i jakością powierzchni. Jeśli jednak wymagane są bardzo drobne poziomy gładkości powierzchni (np. Rz < 3 µm), zalecamy użycie kół szlifujących w wiązce rezynowej z rozmiarami ziarna细分niejszymi niż 150.

Szlifowanie walcowe obejmuje ogólne trzy sposoby: szlifowanie poprzeczne, poziome oraz głębokie.

(1) Szlifowanie poprzeczne

(2) Szlifowanie poziome

(3) Szlifowanie głębokie

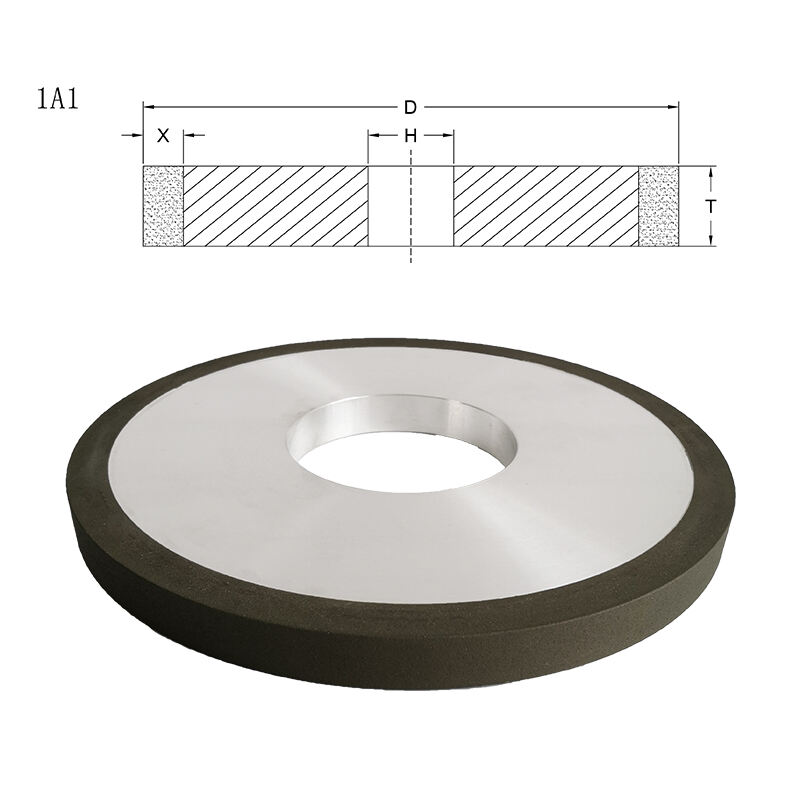

Parametry

| Średnica koła szlifującego D | Szerokość koła szlifującego | Średnica otworu centralnego H |

|

5”, 6”, 7”, 8”, 10”, 12”, 14”, 16”, 18”, 20”, 24”, 30”, 35” 125, 150, 175, 200, 250, 300, 350, 400, 450, 500, 600, 750 i 900mm |

3⁄4”, 1”, 1. 5”, 2” i 3”20, 25, 40, 50 i 75mm |

1/2”, 1”, 1-1/4”, 1,5”, 2”, 3”, 4”, 5” i 12” |

zastosowanie

Koła do wypolerowania cylindrycznego są zazwyczaj stosowane w przemyśle transportowym i warsztatów narzędziowych oraz są idealne do usuwania średniej do dużej ilości materiału. Jeśli martwisz się o żywotność koła i całkowite koszty polerowania na część, nasze koła do wypolerowania cylindrycznego zwiększają produkcyjność i obniżają koszty.

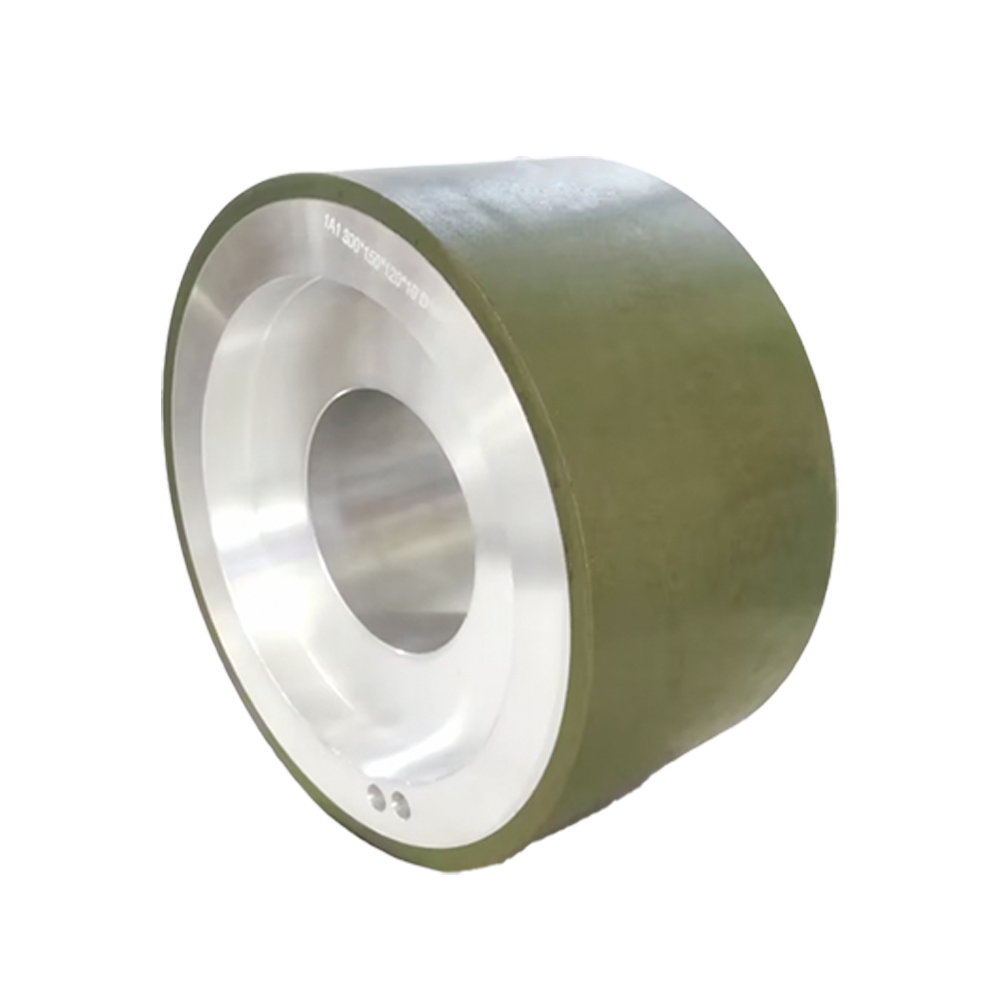

Funkcje:

1. Szybka prędkość spawania, 2~10 razy szybciej niż tradycyjne koła do polerowania.

2. Dostępne od grubego polerowania do polerowania końcowego

3. Przydatne do polerowania różnych materiałów,

4. Wysokie usuwanie materiału

5. Dokładne polerowanie

6. Niski koszt jednostkowy

Copyright © Zhengzhou Ruizuan Diamond Tool Co.,Ltd. All Rights Reserved — Polityka prywatności