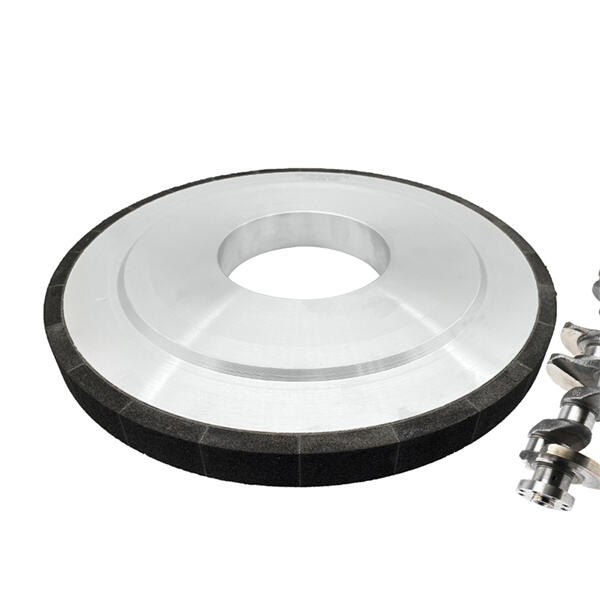

The grinding wheel is one of the most important precision grinding tools we use, when discussing precision grinding. The grinding wheel is an effective tool that assists in shaping, finishing and polishing the surfaces of various materials. Available in multiple sizes and manufactured from different materials, it makes things easier for all types of jobs. The vitrified CBN wheel is one of the increasing types of grinding wheels used in industry.

What is a vitrified CBN wheel exactly? The vitrified CBN wheel is a type of grindin, specifically designed from two key ingredients — ceramic and cubic boron nitride (CBN). CBN particles are extremely hard, comparable to diamond, and this hardness is what makes the CBN so efficient for grinding high-hardness materials. The ceramic component of the wheel binds the CBN particles together, like glue, tighter. The fact that the vitrified CBN wheels boast this combination of structural strength as well as support makes them very ideal in precision grinding.

So, here are some of the best advantages of using vitrified CBN wheels for precision grinding. Among the top benefits they provide is high performance. While standard grinding wheels are typically designed to wear quickly, vitrified CBN is actually intended to maintain its shape and size over many cycles of use. Which means they have a lower repair frequency. This allows workers to use them for longer periods of time, reducing downtime and allowing more work to be done.

Vitrified CBN wheels also offer the ability to achieve extremely smooth and constant finishes. A good, smooth surface finish is often critical in precision grinding. The finish delivered by standard grinding wheels can vary – dependent on wear or how they are being applied in the process. But vitrified CBNwheels are made to deliver consistent finishes time after time. It makes sure that the output will always match the requirements required because everything will be designed to work well in all conditions with an innovative performance.

Another reason why you can get good finishes with these wheels is that they can grind at high speeds without overheating. This is vital as excess temperature can ruin the workpiece. The reason that is allowed is due to low friction between CBN particles and the material being ground. As a result, this translates to lower thermal damage and balance tooling within a cooler grinding process ensuring higher stability & accuracy of workpiece.

Efficiency is a critical factor where significant grinding is taking place. This is where vitrified CBN wheels excel. They help in reducing the downtime as they maintains their shape and size even after use for a longer time. This means that workers get to spend more time grinding, and less time waiting for their tools to change. And because these wheels provide an even finishing, it usually requires lesser passes to achieve the desired result. It saves time, and helps boost overall efficiency.

Finally, it should be a known fact that vitrified CBN wheels are quite universal tools. Big range of materials can be ground, so it can be used where ever. With them, for instance, very hard materials (carbides and ceramics) can pulverize just as readily as more common metal such as iron and steel. They are ideal for surface, cylindrical, and many other grinding operations. This flexibility implies that these wheels can conform to the different requirements and assist in finishing various grinding applications.

REZZ is a grinding wheel maker since 2014 and we have a wealth of experience providing grinding wheel solutions. We offer a wide range of custom Diamond CBN grinding wheel services that help our industrial and manufacturing customers produce better-quality products as well as reduce their operating cost.

We recognize that each client has unique needs. We offer a variety of customizable and custom grinding wheel solutions tailored to specific needs. In close collaboration with our clients, we create customized products that improve their effectiveness in operation, focusing on satisfaction of the customer.

Our highly skilled research and development team continually investigates new materials and processes, positioning us at the top of the market for abrasives. With a strong emphasis on performance and sustainability We strive to offer high-quality, efficient grinding solutions that can meet the changing demands of our customers. We are your trusted partner for excellence, innovation, and high-quality in all grinding processes.

We're committed to delivering the highest quality products and outstanding service. We implement rigorous quality control methods to make sure that each and every one of our grinding wheels is in line with industry standards. This provides our customers with peace of mind and reassurance. Our customer service team will be available at all times to assist and ensure that you have a smooth journey from order to delivery.

Copyright © Zhengzhou Ruizuan Diamond Tool Co.,Ltd. All Rights Reserved — Privacy Policy