תיאור:

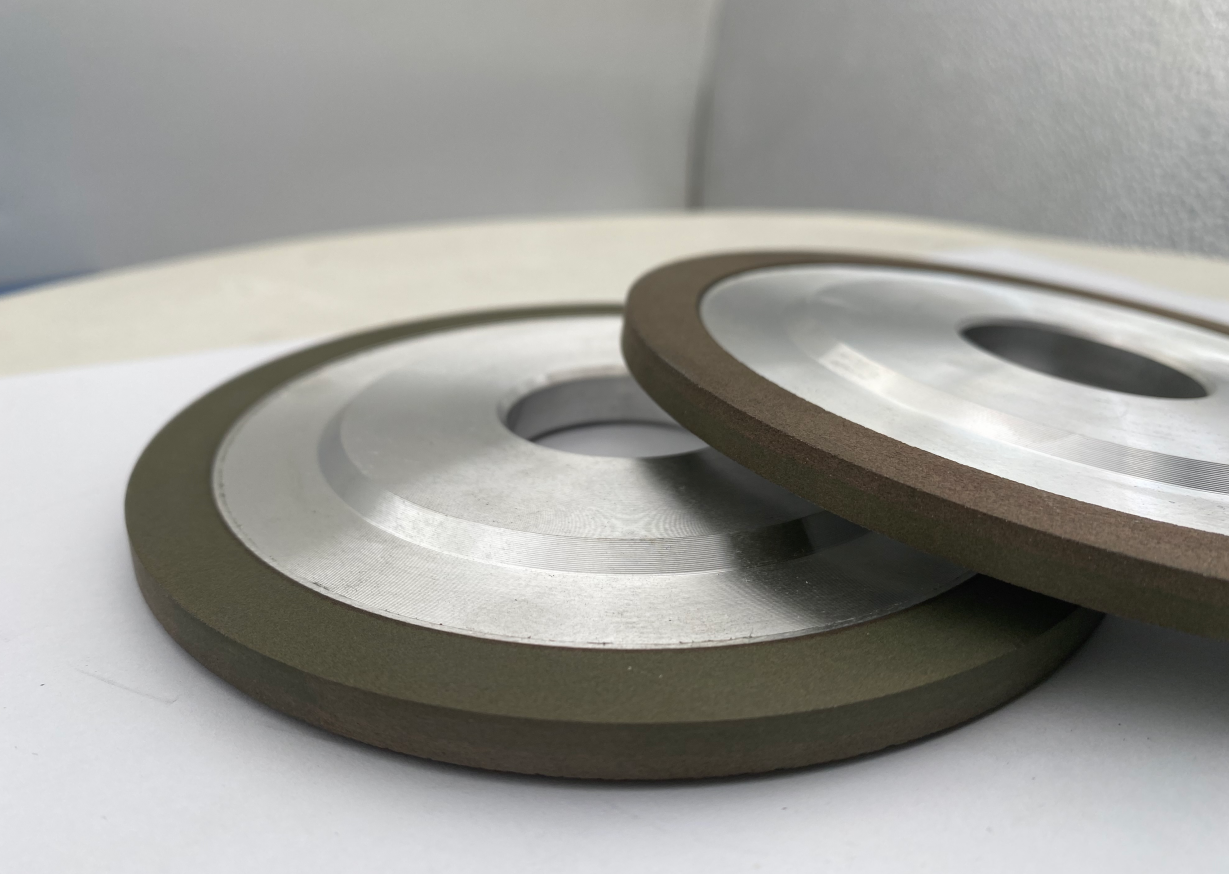

טונגסטן קרביד (קרביד מחובר) הוא מתכת קשה מאוד שאינה נמצאת בקבוצת הפלדים, וגלילי גרinda עם יהלום הם הבחירה האידיאלית לגרירתו. מכיוון שטונגסטן קרביד הוא קשה מאוד, בדרך כלל בין HRC 60 ל-85. לכן, גלילי גרinda מסורתיים לא יכולים לגרר אותו בצורה טובה. יהלום הוא החומר המגרד הקשה ביותר. גליל גרinda עם חיבור רזין ויהלום יכול לגרר את טונגסטן הקרביד ללא הגבלה. בין אם מדובר בחומרים גולמיים של טונגסטן קרביד (שיש, לוח, פלטת או דיסק), כליםbuat טונגסטן קרביד, או כיסוי טונגסטן קרביד, גלילי הגרinda שלנו יכולים לגרר מהר עם גמר מצוין.

תעשיה רלוונטית: חיתוך כלים CNC, חיתוך כלים לעיבוד עץ. דלקה תרמית מסויימת, גרירת פלטנים סיליקוניים. וכו'

חומרי גוף עבודה: גרירת כלים לחתיכה מחומרים כמו קרביד טונגסטן, קרמיום. חומרים מגנטיים, סיליקון. זכוכית, קוורץ ועופרת תרמית. וכו'

סוגי אבני גרירה: 1AIR,1A1,3A1.1V.4A2.4BT9.6A2.1V9.12A2.14F. וכו'

Moresuperhard מספקת אבני גרירה עבור הגרירות הבאות

ת Pebahot:

– תעשיית הרכב. גרירת החור הפנימי של הגלגל והצינור, גרירת החור הפנימי של מפרק המהיר, גרירת החור הפנימי והשיפוע של חלקי מזגן, גרירת הקוטר החיצוני של ציר הפלט הקמוי, גרירת החור הפנימי והצורה של חלקי מערכת הזרקת הדלק, גרירת הקוטרים הפנימי והחיצוני של יד שסתום. מודל מישורי, גרירת קוטר פנימי וחיצוני, גרירת צורה, גרירת צורת הרפרף

– חיתוך מתכת, תעשיית עיבוד כלים. גרירת סכינים מילינג, גרירת שיניים של כלים לתהודה, גרירת שיניים של כלים להוב, גרירת חורים פנימיים, גרירת סכינים מעגליים, סכינים ארוכים, סכינים חיתוך, גרירת חוטים של מolds תפריט, גרירת קוטרים פנימיים, גרירת שיניים של מסגרת踞

– תעשיית כדוריות. גרירת קוטר פנימי של כדוריות, גרירת חריץ של כדוריות, גרירת קוטר פנימי של כדוריות דקיקות, גרירת חריץ, גרירת קוטרים פנימיים וחיצוניים של כדוריות לתעשיית אירוס페이ס, גרירת חריץ חיצוני של מסלול ישר, גרירת קוטר מרכזית ללא מרכז, גרירת ציר כדור

– תעשיית גלגילים. גרירת קוטרים פנימיים וחיצוניים של גלגילים, גרירת שיניים של גלגילי תהודה

– תעשיית מכשירי הבית. חלקים של מקרש, גרירת קוטר פנימי וחריץ, גרירה מרכזית ללא מרכז של צירים

– תעשיית מolds. גרירת קוטרים פנימיים וחיצוניים של מolds, גרירתFACE, גרירת צורה FACE

– תעשיית הציפוי התרמי

– גרירת לוחות חומרה של חומרי חלוק

– תעשיית הרפואה

–瓷 חשמל מדויק

– עיבוד זכוכית אופטית

מפרט:

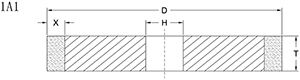

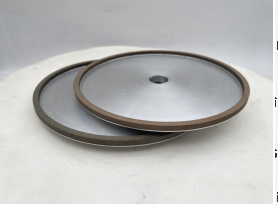

גלגל יהלום 1A1, גלגל יהלום שטוח לשבירת קARBIDE (משתמש להכנת קARBIDE מוסגר HVOF, גלגל קARBIDE, חומר קרמי וזכוכית וכו '. קוטר הגלגלים משתנה מ-25 מ"מ (1 ") עד 915 מ"מ (36 ").

| 1A1 | DxTxH | UxX | הדבקה | גרניט | Con. | abrasives | |

|

25x20x6 | 25x20 | B201/B202/B601 |

D213 D181 D151 D126 D107 D91 D76 D64 D54 D46 |

60 80 100 120 150 180 200 240 280 320 400 |

75 100 125 |

SD SDC |

| 30x25x10 | 25x5 | B201/B202/B601 | |||||

| 35x25x12 | 25x5 | B201/B202/B601 | |||||

| 50x25x20 | 25x5 | B201/B202/B601 | |||||

| 75x25x20 | 25x10 | B201/B202/B601 | |||||

| 100x25x32 | 25x10 | B201/B202/B601 | |||||

| 125x10x32 | 10x10 | B201/B202/B601 | |||||

| 150x15x32 | 15x10 | B201/B202/B601 | |||||

| 200x25x32 | 25x10 | B201/B202/B601 | |||||

| 250x25x76.2 | 25x10 | B201/B202/B601 | |||||

| 350x25x127 | 25x10 | B201/B202/B601 | |||||

| 400x25x127 | 25x10 | B201/B202/B601 | |||||

| 500x50x203.2 | 50x10 | B201/B202/B601 | |||||

| 600x50x304.8 | 50x10 | B201/B202/B601 | |||||

| 750x50x304.8 | 50x10 | B201/B202/B601 | |||||

| 900x50x304.8 | 50x10 | B201/B202/B601 | |||||

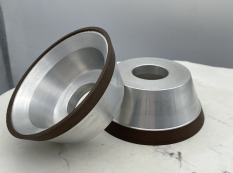

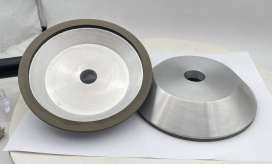

גלגל יהלום רזין לבקרת כלים CNC (חיתוך חרוטים, גשוש קצה צלול וזוית התמיכה, גרירת OD של חומרים כמו כרסיל טונגסטן, מסרקות HSS, מסטול, מחורב והכלה)

| 11V9 12V9 15V9 | DxTxH | UxX | הדבקה | גרניט | Con. | abrasives | |

|

|

75x30x20 | 3x7 | B201/B202/B601 | D213D181D151D126D107D91D76D64D54D46 | 6080100120150180200240280320400 | 75100125 | SDSDC |

| 100x38x32 | 3x10 | B201/B202/B601 | |||||

| 125x38x32 | 3x10 | B201/B202/B601 | |||||

| 150x40x32 | 3x10 | B201/B202/B601 | |||||

| 200x40x32 | 3x10 | B201/B202/B601 | |||||

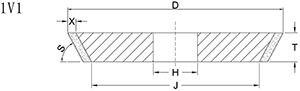

| 1V1 | DxTxH | UxX | הדבקה | גרניט | Con. | abrasives | |

|

75x5x20 | 5X5 | B201/B202/B601 |

D213 D181 D151 D126 D107 D91 D76 D64 D54 D46 |

60 80 100 120 150 180 200 240 280 320 400 |

75 100 125 |

SD SDC |

| 100x10x32 | 10x10 | B201/B202/B601 | |||||

| 125x10x32 | 10x10 | B201/B202/B601 | |||||

| 150x15x32 | 15x10 | B201/B202/B601 | |||||

| 200x25x32 | 25x10 | B201/B202/B601 | |||||

| 250x25x76.2 | 25x10 | B201/B202/B601 | |||||

| 300x25x127 | 25x10 | B201/B202/B601 | |||||

| 350x25x127 | 25x10 | B201/B202/B601 | |||||

| 6A2 11A2 | DxTxH | UxX | הדבקה | גרניט | Con. | abrasives | |

|

|

75x20x20 | 5X5 |

B201 /B202 /B601 |

D213 D181 D151 D126 D107 D91 D76 D64 D54 D46 |

60 80 100 120 150 180 200 240 280 320 400 |

75 100 125 |

SD SDC |

| 100x25x32 | 5X5 |

B201 /B202 /B601 |

|||||

| 125x25x32 | 5X5 |

B201 /B202 /B601 |

|||||

| 150x30x32 | 10X5 |

B201 /B202 /B601 |

|||||

| 200x35x76 | 25x10 |

B201 /B202 /B601 |

|||||

| 250x25x76.2 | 10x10 |

B201 /B202 /B601 |

|||||

| 350x40x127 | 10x10 |

B201 /B202 /B601 |

|||||

| 400x40x127 | 10x10 |

B201 /B202 /B601 |

|||||

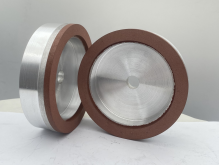

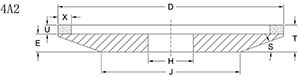

גלגל יהלום רזין לבידוד שיניים של מסך חיתוך קרביד (צורות מיוחדות יכולות להיות מעוצבות לפי תבליט של הלקוח)

| TOP GRINDING 4A2 12A2 |

DxTxH | UxX | הדבקה | גרניט | Con. | abrasives | |

|

75x5x20 | 5X5 | B201/B202/B601 | D213 D181 D151 D126 D107 D91 D76 D64 D54 D46 |

60 80 100 120 150 180 200 240 280 320 400 |

75 100 125 |

SD SDC |

| 100x10x32 | 10x10 | B201/B202/B601 | |||||

| 125x10x32 | 10x10 | B201/B202/B601 | |||||

| 150x15x32 | 15x10 | B201/B202/B601 | |||||

| 200x25x32 | 25x10 | B201/B202/B601 | |||||

| 250x25x76.2 | 25x10 | B201/B202/B601 | |||||

| 300x25x127 | 25x10 | B201/B202/B601 | |||||

| 350x25x127 | 25x10 | B201/B202/B601 | |||||

| 400x25x127 | 25x10 | B201/B202/B601 | |||||

| 500x50x203.2 | 50x10 | B201/B202/B601 | |||||

| 600x50x304.8 | 50x10 | B201/B202/B601 | |||||

|

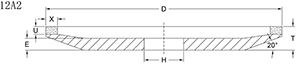

חיתוך פנים 4A2 12A2 12V9 15V9 |

DxTxH | UxX | הדבקה | גרניט | Con. | abrasives | |

|

|

75x5x20 | 5X5 |

B201 /B202 /B601 |

D213 D181 D151 D126 D107 D91 D76 D64 D54 D46 |

60 80 100 120 150 180 200 240 280 320 400 |

75 100 125 |

SD SDC |

| 100x10x32 | 10x10 |

B201 /B202 /B601 |

|||||

| 125x10x32 | 10x10 |

B201 /B202 /B601 |

|||||

| 150x15x32 | 15x10 |

B201 /B202 /B601 |

|||||

| 200x25x32 | 25x10 |

B201 /B202 /B601 |

|||||

| 250x25x76.2 | 25x10 |

B201 /B202 /B601 |

|||||

| 300x25x127 | 25x10 |

B201 /B202 /B601 |

|||||

| 350x25x127 | 25x10 |

B201 /B202 /B601 |

|||||

| 400x25x127 | 25x10 |

B201 /B202 /B601 |

|||||

| 500x50x203.2 | 50x10 | B201/B202/B601 | |||||

| 600x50x304.8 | 50x10 | B201/B202/B601 | |||||

|

חיתוך צדדי 14A1 3A1 |

DxTxH | UxX | הדבקה | גרניט | Con. | abrasives | |

|

|

75x5x20 | 5X5 |

B201 /B202 /B601 |

D213 D181 D151 D126 D107 D91 D76 D64 D54 D46 |

60 80 100 120 150 180 200 240 280 320 400 |

75 100 125 |

SD SDC |

| 100x10x32 | 10x10 |

B201 /B202 /B601 |

|||||

| 125x10x32 | 10x10 |

B201 /B202 /B601 |

|||||

| 150x15x32 | 15x10 |

B201 /B202 /B601 |

|||||

| 200x25x32 | 25x10 |

B201 /B202 /B601 |

|||||

| 250x25x76.2 | 25x10 |

B201 /B202 /B601 |

|||||

| 300x25x127 | 25x10 |

B201 /B202 /B601 |

|||||

| 350x25x127 | 25x10 |

B201 /B202 /B601 |

|||||

| 400x25x127 | 25x10 |

B201 /B202 /B601 |

|||||

| 500x50x203.2 | 50x10 |

B201 /B202 /B601 |

|||||

| 600x50x304.8 | 50x10 |

B201 /B202 /B601 |

|||||

יתרון תחרותי:

1. גרירת מהירה.

בהשוואה לגלגלים מטילים תקניים, גלגלים יקרתיים גררים מהר יותר. כאשר אתה עושה גרירה בכמויות גדולות, הגרירה המהירה עוזרת לך לחסוך הרבה זמן. חיסכון בזמן עוזר לך להפיק רווחים נוספים.

2.仕上げ מצוינות

אם גלגל גרירה אינו חד, תבניות או קווים של רעש יופיעו על החומר. גלגל גרירה יקרתי חד יעזור לך לפתור את הבעיות האלה ויביא שיפוץ משטח מצוין.

3. גרירה קרירה

בגלל הגרירה האפקטיבית, נוצר מעט חום. והגוף האלומיניום עוזר להפיץ את החום במהירות.

4. חיים ארוכים

בגלל הקשיחות הגבוהה של חומרי ההיגד היקרטים, לגלגלים יקרתיים יש חיי שרות ארוכים יותר מאשר לגלגלים מטילים תקניים.

5. פחות איפוס

גלגל גריבה של יהלום חד צריך פחות איפוס

Copyright © Zhengzhou Ruizuan Diamond Tool Co.,Ltd. All Rights Reserved — מדיניותICY