คำอธิบาย:

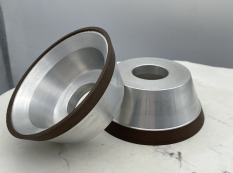

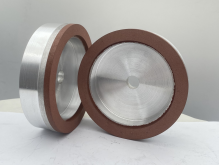

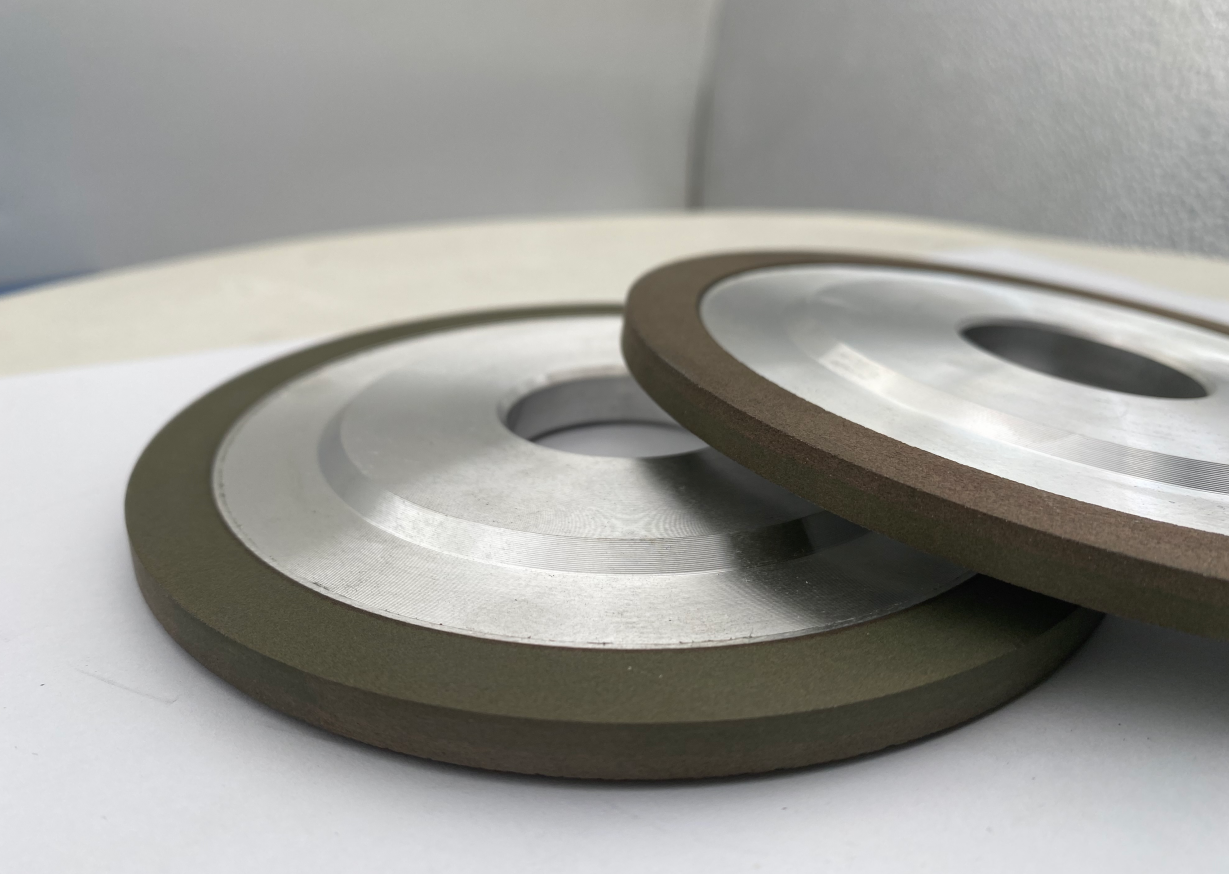

คาร์ไบด์ tengsten (คาร์ไบด์เชื่อม) เป็นโลหะที่แข็งมากไม่มีเหล็ก ล้อขัดเพชรถือเป็นทางเลือกที่เหมาะสมที่สุดในการขัดมัน เนื่องจากคาร์ไบด์ tengsten มีความแข็งมาก ปกติจะอยู่ระหว่าง HRC 60 ถึง 85 ดังนั้นล้อขัดสารขัดทั่วไปไม่สามารถขัดได้ดี เพชรคือสารขัดที่แข็งที่สุด ล้อขัดเพชรที่มีพันธะเรซินสามารถขัดคาร์ไบด์ tengsten ได้อย่างอิสระ ไม่ว่าจะเป็นวัสดุดิบของคาร์ไบด์ tengsten (แท่ง แผ่น แท่ง หรือแผ่นกลม) เครื่องมือคาร์ไบด์ tengsten หรือการเคลือบคาร์ไบด์ tengsten ล้อขัดเพชรอันของเราสามารถขัดได้อย่างรวดเร็วและให้ผิวที่ยอดเยี่ยม

อุตสาหกรรมที่เกี่ยวข้อง: การเจียระไนเครื่องมือ CNC, การเจียระไนเครื่องมืองานไม้ การเคลือบด้วยความร้อน, การเจียระไนแผ่นซิลิกอน ฯลฯ

วัสดุชิ้นงาน: การเจียระไนเครื่องตัดคาร์ไบด์ของ Wolfram, เซรามิก วัสดุแม่เหล็ก ซิลิกอน กระจก ควอตซ์ และโลหะผสมการเคลือบด้วยความร้อน ฯลฯ

ประเภทของจานเจียระไน: 1AIR, 1A1, 3A1, 1V, 4A2, 4BT9, 6A2, 1V9, 12A2, 14F ฯลฯ

Moresuperhard จัดหาจานเจียระไนสำหรับการเจียระไนดังต่อไปนี้

การใช้งาน:

– อุตสาหกรรมยานยนต์ เจียระไนรูพร่องล้อและกระบอกสูบ เจียระไนรูพร่องของข้อต่อความเร็วคงที่ เจียระไนรูพร่องภายในและภายนอกของชิ้นส่วนคอมเพรสเซอร์ เจียระไนเส้นผ่านศูนย์กลางนอกของแกนเอาต์พุตแบบเว้า เจียระไนรูพร่องภายในและรูปทรงของชิ้นส่วนระบบฉีดเชื้อเพลิง เจียระไนเส้นผ่านศูนย์กลางในและนอกของที่จับวาล์ว พื้นผิวแม่พิมพ์ เส้นผ่านศูนย์กลางในและนอก การเจียระไนรูปทรงและการเจียระไนรูปทรงของโรคเกอร์

– อุตสาหกรรมการตัดโลหะและการประมวลผลเครื่องมือ การเจียรดอกสว่าน การเจียรฟันเฟือง การเจียรฟันเกลียวของ Hob cutter การเจียรรูใน การเจียรใบมีดกลม ใบมีดยาว ใบมีดตัด การเจียรเกลียวแม่พิมพ์ การเจียรเส้นผ่าศูนย์กลางภายใน การเจียรใบเลื่อยวงกลม

– อุตสาหกรรมหมุดลูกปืน เจียรเส้นผ่าศูนย์กลางภายในของลูกปืน เจียรร่อง เจียรเส้นผ่าศูนย์กลางภายในของลูกปืนเข็ม เจียรร่อง เจียรเส้นผ่าศูนย์กลางภายในและภายนอกของหมุดลูกปืนสำหรับอุตสาหกรรมการบิน เจียรร่องและเส้นผ่าศูนย์กลางภายนอกของการสไลด์เชิงเส้น เจียรลูกสกรูแบบไร้แกน

– อุตสาหกรรมเกียร์ เจียรเส้นผ่าศูนย์กลางภายในและภายนอกของเกียร์ เจียร Hob

– อุตสาหกรรมเครื่องใช้ไฟฟ้า เจียรเส้นผ่าศูนย์กลางภายในและร่องของชิ้นส่วนคอมเพรสเซอร์ เจียรแบบไร้แกนของแกน

– อุตสาหกรรมแม่พิมพ์ เจียรเส้นผ่าศูนย์กลางภายในและภายนอกของแม่พิมพ์ เจียรผิวเรียบ เจียรรูปร่างบนผิวเรียบ

– อุตสาหกรรมการพ่นความร้อน

– เจียรวาฟเฟอร์กึ่งตัวนำ

– อุตสาหกรรมการแพทย์

– เซรามิกวิศวกรรมความแม่นยำ

– การแปรรูปกระจกออปติคอล

ข้อมูลจำเพาะ:

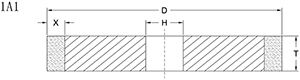

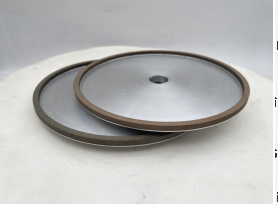

ล้อเพชร 1A1, ล้อเพชรแบนสำหรับการเจียรโลหะคาร์ไบด์ (ใช้สำหรับการเจียรคาร์ไบด์เคลือบที่ผลิตด้วยกระบวนการ HVOF, โรลคาร์ไบด์, เซรามิก และกระจก เป็นต้น เส้นผ่านศูนย์กลางของล้อเจียรอยู่ระหว่าง 25mm (1″) ถึง 915mm (36″)

| 1A1 | DxTxH | UxX | การยึดติด | เม็ดทราย | Con. | วัสดุขัดสึก | |

|

25x20x6 | 25x20 | B201/B202/B601 |

D213 D181 D151 D126 D107 D91 D76 D64 D54 D46 |

60 80 100 120 150 180 200 240 280 320 400 |

75 100 125 |

SD SDC |

| 30x25x10 | 25x5 | B201/B202/B601 | |||||

| 35x25x12 | 25x5 | B201/B202/B601 | |||||

| 50x25x20 | 25x5 | B201/B202/B601 | |||||

| 75x25x20 | 25X10 | B201/B202/B601 | |||||

| 100x25x32 | 25X10 | B201/B202/B601 | |||||

| 125x10x32 | 10x10 | B201/B202/B601 | |||||

| 150x15x32 | 15X10 | B201/B202/B601 | |||||

| 200x25x32 | 25X10 | B201/B202/B601 | |||||

| 250x25x76.2 | 25X10 | B201/B202/B601 | |||||

| 350x25x127 | 25X10 | B201/B202/B601 | |||||

| 400x25x127 | 25X10 | B201/B202/B601 | |||||

| 500x50x203.2 | 50x10 | B201/B202/B601 | |||||

| 600x50x304.8 | 50x10 | B201/B202/B601 | |||||

| 750x50x304.8 | 50x10 | B201/B202/B601 | |||||

| 900x50x304.8 | 50x10 | B201/B202/B601 | |||||

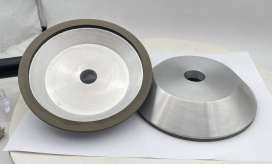

ล้อเพชรเรซินสำหรับการเจียรเครื่องมือ CNC (การทำ flute, การ gashing, การล้างขอบและการปรับมุมความเอียง, การเจียร OD ของวัสดุคาร์ไบด์ เหล็กกล้า高速 (HSS), เครื่องมิลลิ่ง, reamer และดอกสว่าน เป็นต้น)

| 11V9 12V9 15V9 | DxTxH | UxX | การยึดติด | เม็ดทราย | Con. | วัสดุขัดสึก | |

|

|

75x30x20 | 3X7 | B201/B202/B601 | D213D181D151D126D107D91D76D64D54D46 | 6080100120150180200240280320400 | 75100125 | SDSDC |

| 100x38x32 | 3X10 | B201/B202/B601 | |||||

| 125x38x32 | 3X10 | B201/B202/B601 | |||||

| 150x40x32 | 3X10 | B201/B202/B601 | |||||

| 200x40x32 | 3X10 | B201/B202/B601 | |||||

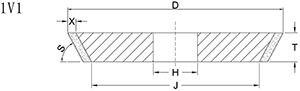

| 1V1 | DxTxH | UxX | การยึดติด | เม็ดทราย | Con. | วัสดุขัดสึก | |

|

75x5x20 | 5x5 | B201/B202/B601 |

D213 D181 D151 D126 D107 D91 D76 D64 D54 D46 |

60 80 100 120 150 180 200 240 280 320 400 |

75 100 125 |

SD SDC |

| 100x10x32 | 10x10 | B201/B202/B601 | |||||

| 125x10x32 | 10x10 | B201/B202/B601 | |||||

| 150x15x32 | 15X10 | B201/B202/B601 | |||||

| 200x25x32 | 25X10 | B201/B202/B601 | |||||

| 250x25x76.2 | 25X10 | B201/B202/B601 | |||||

| 300x25x127 | 25X10 | B201/B202/B601 | |||||

| 350x25x127 | 25X10 | B201/B202/B601 | |||||

| 6A2 11A2 | DxTxH | UxX | การยึดติด | เม็ดทราย | Con. | วัสดุขัดสึก | |

|

|

75x20x20 | 5x5 |

B201 /B202 /B601 |

D213 D181 D151 D126 D107 D91 D76 D64 D54 D46 |

60 80 100 120 150 180 200 240 280 320 400 |

75 100 125 |

SD SDC |

| 100x25x32 | 5x5 |

B201 /B202 /B601 |

|||||

| 125x25x32 | 5x5 |

B201 /B202 /B601 |

|||||

| 150x30x32 | 10X5 |

B201 /B202 /B601 |

|||||

| 200x35x76 | 25X10 |

B201 /B202 /B601 |

|||||

| 250x25x76.2 | 10x10 |

B201 /B202 /B601 |

|||||

| 350x40x127 | 10x10 |

B201 /B202 /B601 |

|||||

| 400x40x127 | 10x10 |

B201 /B202 /B601 |

|||||

ล้อเพชรเรซินสำหรับการเจียรใบเลื่อยวงกลมคาร์ไบด์ (รูปร่างพิเศษสามารถออกแบบตามแบบของลูกค้าได้)

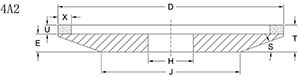

| TOP GRINDING 4A2 12A2 |

DxTxH | UxX | การยึดติด | เม็ดทราย | Con. | วัสดุขัดสึก | |

|

75x5x20 | 5x5 | B201/B202/B601 | D213 D181 D151 D126 D107 D91 D76 D64 D54 D46 |

60 80 100 120 150 180 200 240 280 320 400 |

75 100 125 |

SD SDC |

| 100x10x32 | 10x10 | B201/B202/B601 | |||||

| 125x10x32 | 10x10 | B201/B202/B601 | |||||

| 150x15x32 | 15X10 | B201/B202/B601 | |||||

| 200x25x32 | 25X10 | B201/B202/B601 | |||||

| 250x25x76.2 | 25X10 | B201/B202/B601 | |||||

| 300x25x127 | 25X10 | B201/B202/B601 | |||||

| 350x25x127 | 25X10 | B201/B202/B601 | |||||

| 400x25x127 | 25X10 | B201/B202/B601 | |||||

| 500x50x203.2 | 50x10 | B201/B202/B601 | |||||

| 600x50x304.8 | 50x10 | B201/B202/B601 | |||||

|

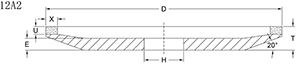

การเจียรหน้า 4A2 12A2 12V9 15V9 |

DxTxH | UxX | การยึดติด | เม็ดทราย | Con. | วัสดุขัดสึก | |

|

|

75x5x20 | 5x5 |

B201 /B202 /B601 |

D213 D181 D151 D126 D107 D91 D76 D64 D54 D46 |

60 80 100 120 150 180 200 240 280 320 400 |

75 100 125 |

SD SDC |

| 100x10x32 | 10x10 |

B201 /B202 /B601 |

|||||

| 125x10x32 | 10x10 |

B201 /B202 /B601 |

|||||

| 150x15x32 | 15X10 |

B201 /B202 /B601 |

|||||

| 200x25x32 | 25X10 |

B201 /B202 /B601 |

|||||

| 250x25x76.2 | 25X10 |

B201 /B202 /B601 |

|||||

| 300x25x127 | 25X10 |

B201 /B202 /B601 |

|||||

| 350x25x127 | 25X10 |

B201 /B202 /B601 |

|||||

| 400x25x127 | 25X10 |

B201 /B202 /B601 |

|||||

| 500x50x203.2 | 50x10 | B201/B202/B601 | |||||

| 600x50x304.8 | 50x10 | B201/B202/B601 | |||||

|

การเจียรด้านข้าง 14A1 3A1 |

DxTxH | UxX | การยึดติด | เม็ดทราย | Con. | วัสดุขัดสึก | |

|

|

75x5x20 | 5x5 |

B201 /B202 /B601 |

D213 D181 D151 D126 D107 D91 D76 D64 D54 D46 |

60 80 100 120 150 180 200 240 280 320 400 |

75 100 125 |

SD SDC |

| 100x10x32 | 10x10 |

B201 /B202 /B601 |

|||||

| 125x10x32 | 10x10 |

B201 /B202 /B601 |

|||||

| 150x15x32 | 15X10 |

B201 /B202 /B601 |

|||||

| 200x25x32 | 25X10 |

B201 /B202 /B601 |

|||||

| 250x25x76.2 | 25X10 |

B201 /B202 /B601 |

|||||

| 300x25x127 | 25X10 |

B201 /B202 /B601 |

|||||

| 350x25x127 | 25X10 |

B201 /B202 /B601 |

|||||

| 400x25x127 | 25X10 |

B201 /B202 /B601 |

|||||

| 500x50x203.2 | 50x10 |

B201 /B202 /B601 |

|||||

| 600x50x304.8 | 50x10 |

B201 /B202 /B601 |

|||||

Competitive Advantage:

1. เจียรเร็ว

เมื่อเปรียบเทียบกับล้อเจียรชนิดทั่วไป ล้อเจียรเพชรสามารถเจียรได้เร็วกว่า เมื่อคุณต้องเจียรอย่างต่อเนื่อง การเจียรที่รวดเร็วจะช่วยให้คุณประหยัดเวลาได้มาก และยังช่วยเพิ่มกำไรให้คุณ

2. ผิวงานยอดเยี่ยม

หากล้อเจียรไม่คม จะทำให้เกิดร่องหรือเส้นบนชิ้นงาน ล้อเจียรเพชรที่คมจะช่วยแก้ปัญหาเหล่านี้และมอบผิวงานที่ยอดเยี่ยม

3. เจียรเย็น

เนื่องจากเจียรอย่างมีประสิทธิภาพสูง ความร้อนที่เกิดขึ้นจึงน้อยลง และตัวล้ออะลูมิเนียมสามารถช่วยกระจายความร้อนได้อย่างรวดเร็ว

4. อายุการใช้งานยาวนาน

เนื่องจากความแข็งสูงของเม็ดสANDINGเพชร ล้อเพชรจึงมีอายุการใช้งานที่ยาวนานกว่าล้อขัดชนิดทั่วไป

5. ต้องปรับแต่งน้อยกว่า

ล้อเพชรขัดที่คมต้องการการปรับแต่งน้อยกว่า

Copyright © Zhengzhou Ruizuan Diamond Tool Co.,Ltd. All Rights Reserved — นโยบายความเป็นส่วนตัว