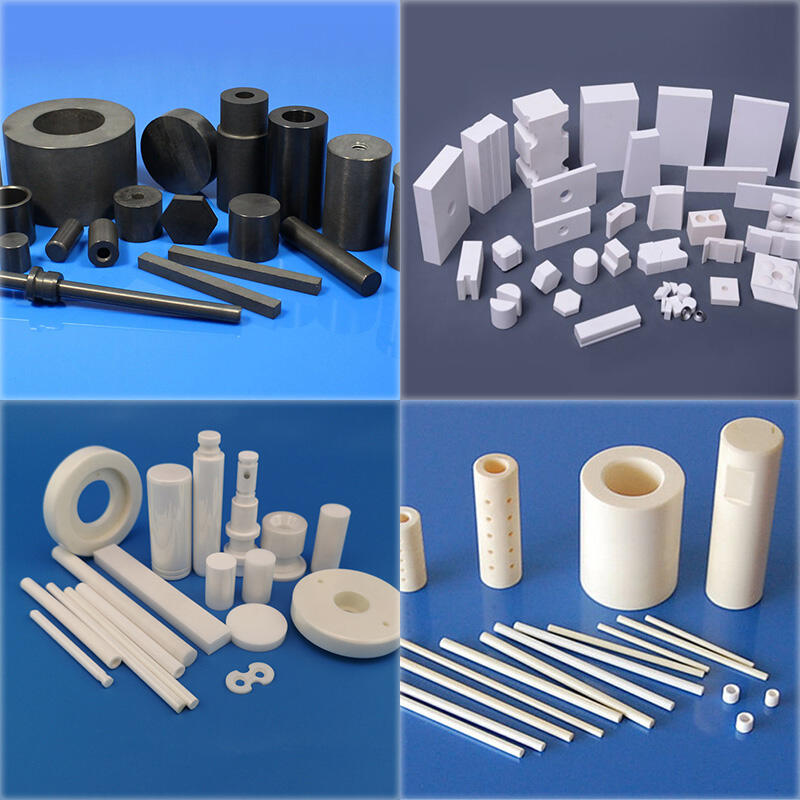

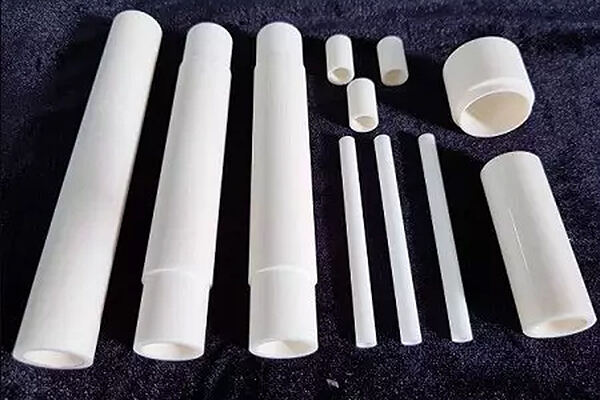

Hard Ceramic is famous for its hardness. They are broadly applied in industrial machine parts, Analytical Instruments, medical parts, semi-conductor, solar energy, automotive, aerospace and etc.

Quick Detail:

Hard Ceramic is famous for its hardness. They are broadly applied in industrial machine parts, Analytical Instruments, medical parts, semi-conductor, solar energy, automotive, aerospace and etc.

Description:

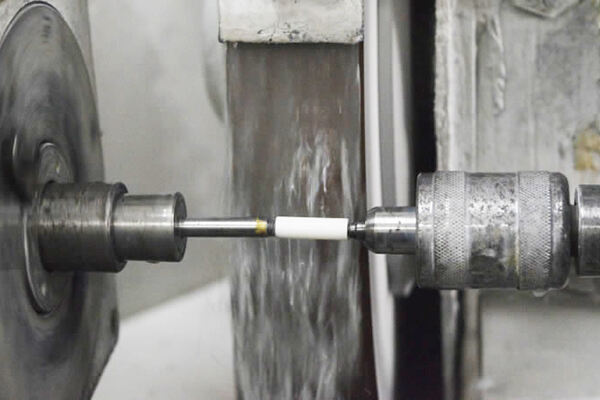

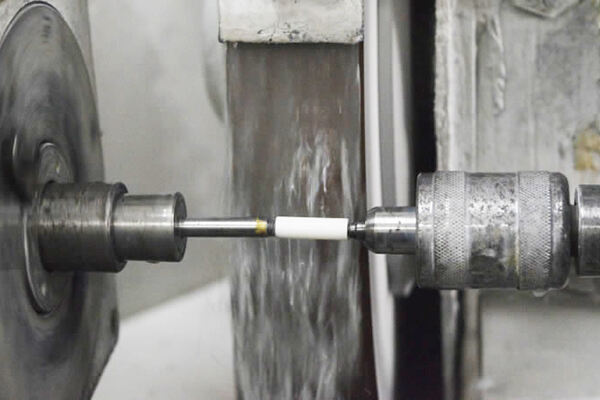

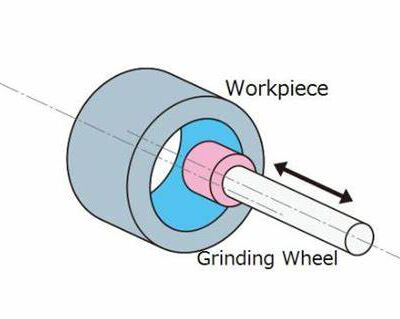

RZ offers custom precision ceramic grinding, lapping and polishing service and solution. Ceramic is difficult to cut with normal machining method in precision intricate profile. The grinding process with diamond grinding wheel is an effective process to machining ceramic materials. The tolerance of intricate profiler precision degree by this grinding process is less than 0. 005mm. The machining process contains high efficiency of profiler dressing technique of diamond wheel and form grinding process of ceramic.

Hard Ceramic is famous for its hardness. They are broadly applied in industrial machine parts, Analytical Instruments, medical parts, semi-conductor, solar energy, automotive, aerospace and etc.

Diamond is the hardest abrasives. A resin bond diamond grinding wheels can free grind Hard ceramic. Diamond can grind all kinds of ceramics, Alumina Ceramic, Zirconia Ceramics, Silicon Nitride CeramicsBoron Nitride Ceramics, Silicon Carbide Ceramics, Boron Carbide Ceramics

1. 1. 1 Application

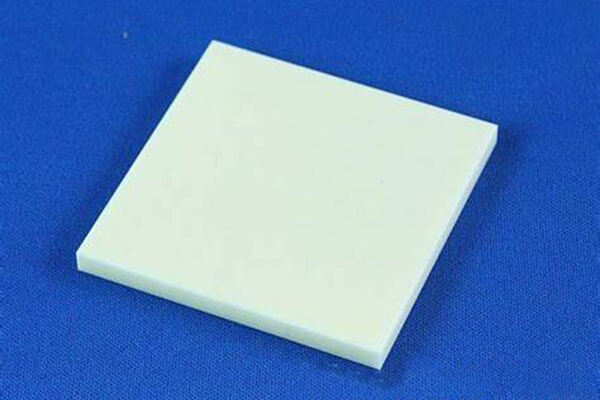

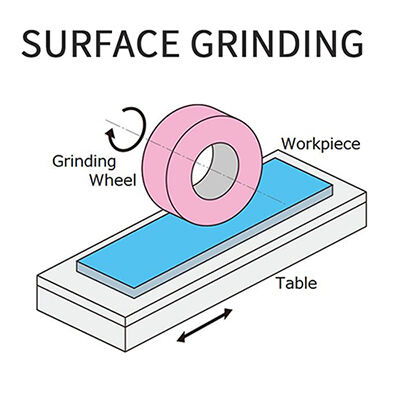

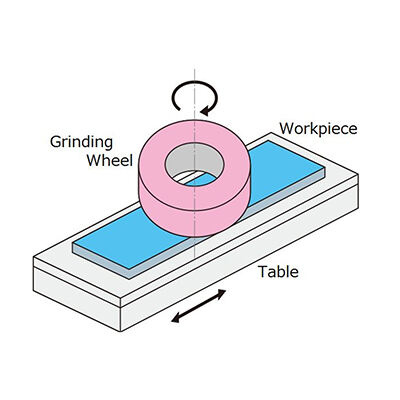

1. Ceramic plate surface grinding

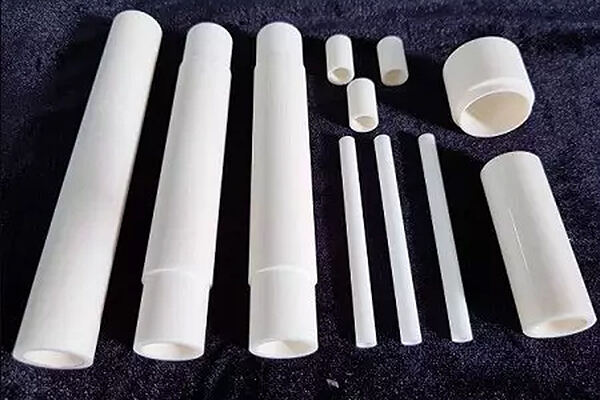

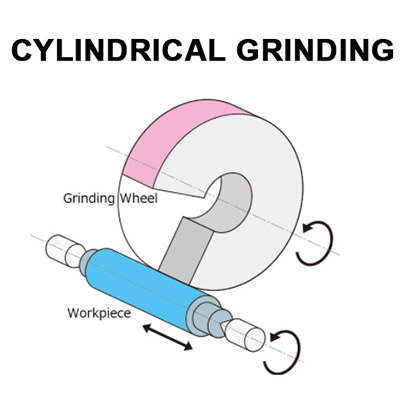

2. Ceramic rod cylindrical grinding

3. Profile grinding of ceramic

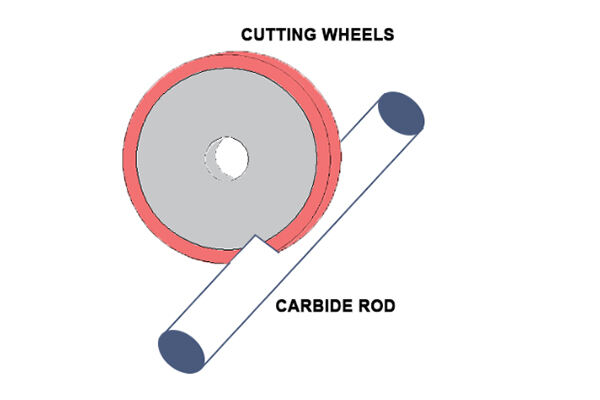

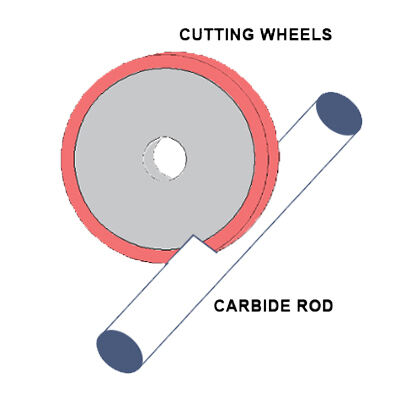

4. Cutting wheels for Ceramic cutting or slotting

Specifications:

| Flat 1A1, 3A1, 14A1 | DxTxH | UxX | Bonding | Grit | Con. | Abrasives | |

|

75x5x20 | 5x5 |

B201 /B202 /B601 |

D213 D181 D151 D126 D107 D91 D76 D64 D54 D46 |

60 80 100 120 150 180 200 240 280 320 400 |

75 100 125 |

SD SDC |

| 100x10x32 | 10x10 |

B201 /B202 /B601 |

|||||

| 125x10x32 | 10x10 |

B201 /B202 /B601 |

|||||

| 150x15x32 | 15x10 |

B201 /B202 /B601 |

|||||

| 200x25x32 | 25x10 |

B201 /B202 /B601 |

|||||

| 250x25x76. 2 | 25x10 |

B201 /B202 /B601 |

|||||

| 350x25x127 | 25x10 |

B201 /B202 /B601 |

|||||

| 400x25x127 | 25x10 |

B201 /B202 /B601 |

|||||

| 500x50x203. 2 | 50x10 |

B201 /B202 /B601 |

|||||

| 600x50x304. 8 | 50x10 |

B201 /B202 /B601 |

|||||

| Cup 6A2, 1A2, 2A2 | DxTxH | UxX | Bonding | Grit | Con. | Abrasives | |

|

100x20x32 | 5x5 |

B201 /B202 /B601 |

D213 D181 D151 D126 D107 D91 D76 D64 D54 D46 |

60 80 100 120 150 180 200 240 280 320 400 |

75 100 125 |

SD SDC |

| 125x25x32 | 5x5 |

B201 /B202 /B601 |

|||||

| 150x25x32 | 10x10 |

B201 /B202 /B601 |

|||||

| 200x25x32 | 25x10 |

B201 /B202 /B601 |

|||||

| 250x25x76.2 | 25x10 |

B201 /B202 /B601 |

|||||

| 350x25x127 | 25x10 |

B201 /B202 /B601 |

|||||

| 400x25x127 | 25x10 |

B201 /B202 /B601 |

|||||

| 500x50x203.2 | 50x10 |

B201 /B202 /B601 |

|||||

| 600x50x304.8 | 50x10 |

B201 /B202 /B601 |

|||||

| Super Thin 1A1R | DxTxH | UxX | Bonding | Grit | Con. | Abrasives | |

|

50X0.5X20 | 0.5X5 |

B201 /B202 /B601 |

D213 D181 D151 D126 D107 D91 D76 D64 D54 D46 |

60 80 100 120 150 180 200 240 280 320 400 |

75 100 125 |

SD SDC |

| 75X0.8X20 | 0.8X5 |

B201 /B202 /B601 |

|||||

| 100x1x20 | 1x10 |

B201 /B202 /B601 |

|||||

| 125x1x31.75 | 1x10 |

B201 /B202 /B601 |

|||||

| 150x1x31.75 | 1x10 |

B201 /B202 /B601 |

|||||

| 175x1x31.75 | 25x10 |

B201 /B202 /B601 |

|||||

| 200X1X31.75 | 1X10 |

B201 /B202 /B601 |

|||||

| 250x1.2x31.75 | 1.2x10 |

B201 /B202 /B601 |

|||||

| 300x1.5x50.8 | 1.5x10 |

B201 /B202 /B601 |

|||||

| 350x1.5x50.8 | 1.5x10 |

B201 /B202 /B601 |

|||||

| 400x2x76.2 | 1.5x10 |

B201 /B202 /B601 |

|||||

| 1A1 | DxTxH | UxX | Bonding | Grit | Con. | Abrasives | |

|

125x10x32 | 10x10 | B201/B202/B601 |

D213 D181 D151 D126 D107 D91 D76 D64 D54 D46 |

60 80 100 120 150 180 200 240 280 320 400 |

75 100 125 |

SD SDC |

| 150x15x32 | 15x10 | B201/B202/B601 | |||||

| 200x25x32 | 25x10 | B201/B202/B601 | |||||

| 250x25x76.2 | 25x10 | B201/B202/B601 | |||||

| 350x25x127 | 25x10 | B201/B202/B601 | |||||

| 400x25x127 | 25x10 | B201/B202/B601 | |||||

| 500x50x203.2 | 50x10 | B201/B202/B601 | |||||

| 600x50x304.8 | 50x10 | B201/B202/B601 | |||||

| 750x50x304.8 | 50x10 | B201/B202/B601 | |||||

| 900x50x304.8 | 50x10 | B201/B202/B601 | |||||

| 1A1 | DxTxH | UxX | Bonding | Grit | Con. | Abrasives | |

|

10x10x6 | 10x10 |

B201 /B202 /B601 |

D213 D181 D151 D126 D107 D91 D76 D64 D54 D46 |

60 80 100 120 150 180 200 240 280 320 400 |

75 100 125 |

SD SDC |

|

12x15x6 |

12x15 |

B201 /B202 /B601 |

|||||

| 15x15x6 | 15x15 |

B201 /B202 /B601 |

|||||

| 20x20x6 | 20x20 |

B201 /B202 /B601 |

|||||

| 25x20x6 | 20x20 |

B201 /B202 /B601 |

|||||

| 30x25x10 | 25x5 |

B201 /B202 /B601 |

|||||

| 35x25x10 | 25x5 |

B201 /B202 /B601 |

|||||

| 50x25x20 | 25x5 |

B201 /B202 /B601 |

|||||

| 75x25x20 | 25x10 |

B201 /B202 /B601 |

|||||

| 100x25x32 | 25x10 |

B201 /B202 /B601 |

|||||

| 125x10x32 | 10x10 |

B201 /B202 /B601 |

|||||

Features:

1.Fast grinding.

Comparing conventional abrasive wheels, Diamond wheels grind faster. When you do quantity grinding, the fast grinding help you save a lot of time. Saving time and help you make more profits.

2.Excellent finishes

If a grinding wheel is not sharp, chatter waves or lines will appear on workpiece. A sharp diamond grinding wheels will help you solve these problems and bring an excellent surface finish.

3.Cool Grinding

Due to highly efficient grinding, less heat generated. And the aluminum body can help heat spread quickly.

4.Long lifespan

Due to the high hardness of diamond abrasives, Diamond wheels has extra longer lifespan than conventional abrasive wheels.

5.Less dressing

A sharp diamond grinding wheels needs less dressing

Copyright © Zhengzhou Ruizuan Diamond Tool Co.,Ltd. All Rights Reserved — Privacy Policy