The bond of the mixed bond diamond grinding wheel is composed of a mixture of metal and resin. After electrolytic dressing, the surface metal dissolves to form an elastic resin-based grinding layer, while the internal bond still maintains a high-rigidity metal-resin mixed matrix. This enables the mixed bond grinding wheel to obtain better surface/sub-surface quality while ensuring the accuracy of the grinding surface.

For Solid Carbide or HSS Tools Fluting,Gashing or OD Grinding on CNC grinding machines, it always needs a super quality Diamond CBN Wheels.RZ develops G-Power Diamond CBN grinding Wheels for this industry.

REZZ will provide you with system solutions for industries such as carbide and high-speed steel tools, dirlls, endmills or blade grinding.

Hybrid Bond Features:

* High profile retention ability

* Sharp & Fast grinding

* Excellent surface finishes

* Less dressing interval

* High productivity

|

|

|

|

Grinding Methods:

| 1 | Cylindrical Grinding |

| 2 | sharpening |

| 3 | Fulting |

| 4 | Gashing |

|

|

Application:

Grinding Workpiece: Soild carbide/ HSS round tools & inserts, like endmills, drills, milling tools and others.

Applicable Tool Material: carbide materials, steel materials, etc.

Applicable Grinding Machine: ANCA, WALTER, SCHUTTE, EWAG, SCHNEEBERGER, HUFFMANN And So On.

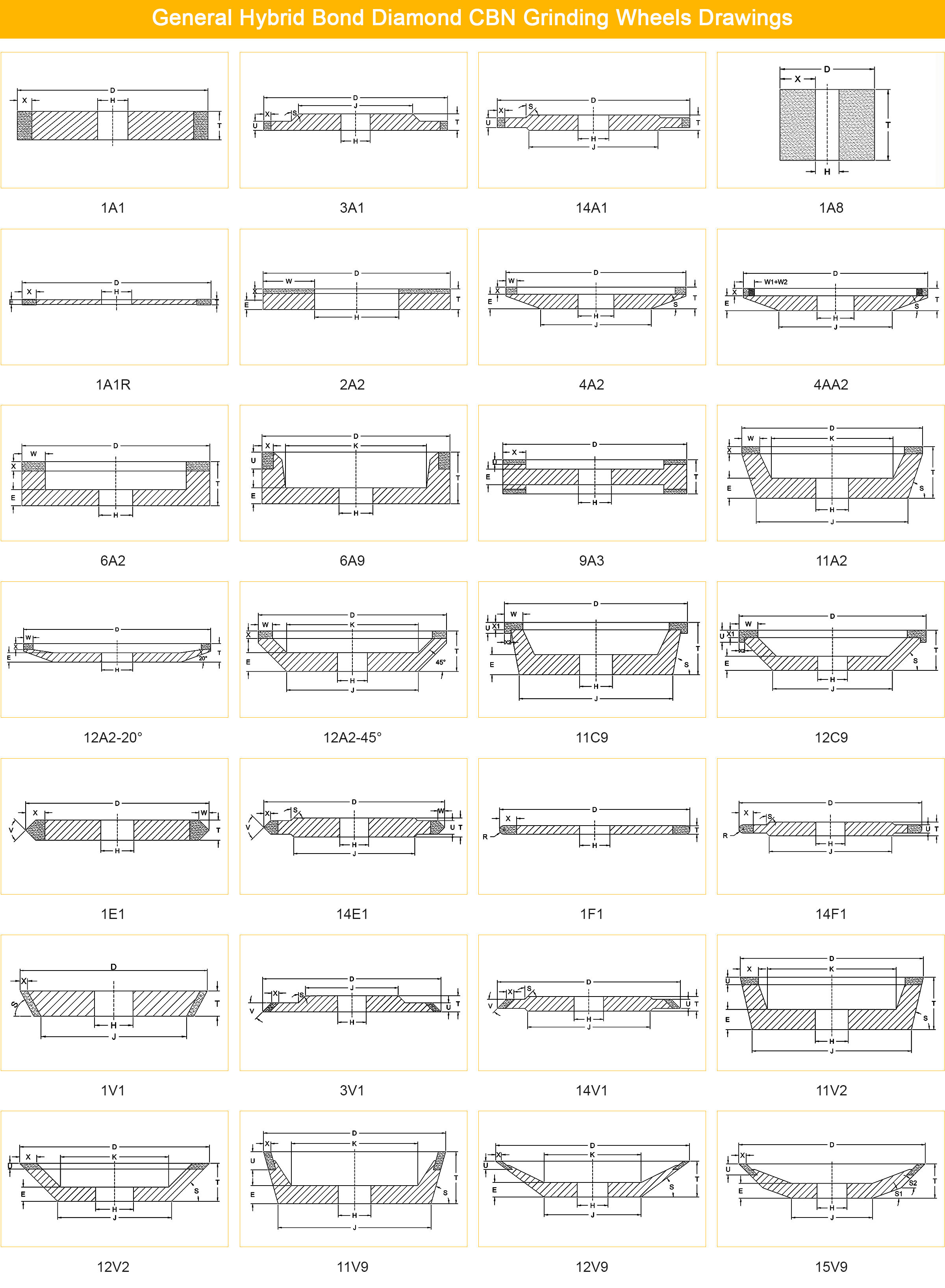

Specifications:

| Dimensions | ||||

| D(mm) | Bond | Grit | Concentration | Concentration |

| 75-200 | Resin/ Hybrid | 80-400 | 100, 125, 150 | 100, 125, 150 |

Copyright © Zhengzhou Ruizuan Diamond Tool Co.,Ltd. All Rights Reserved — Privacy Policy