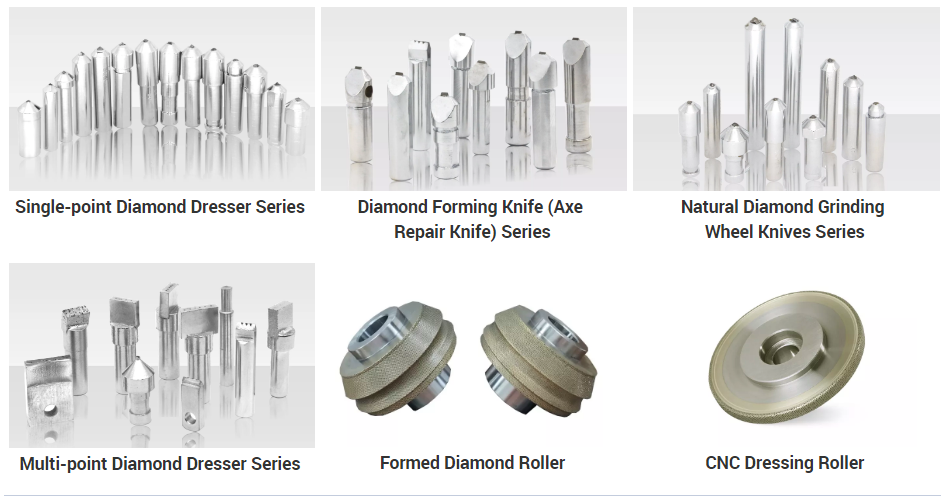

1.Metal Bond Diamond Dressing Wheels and Tools

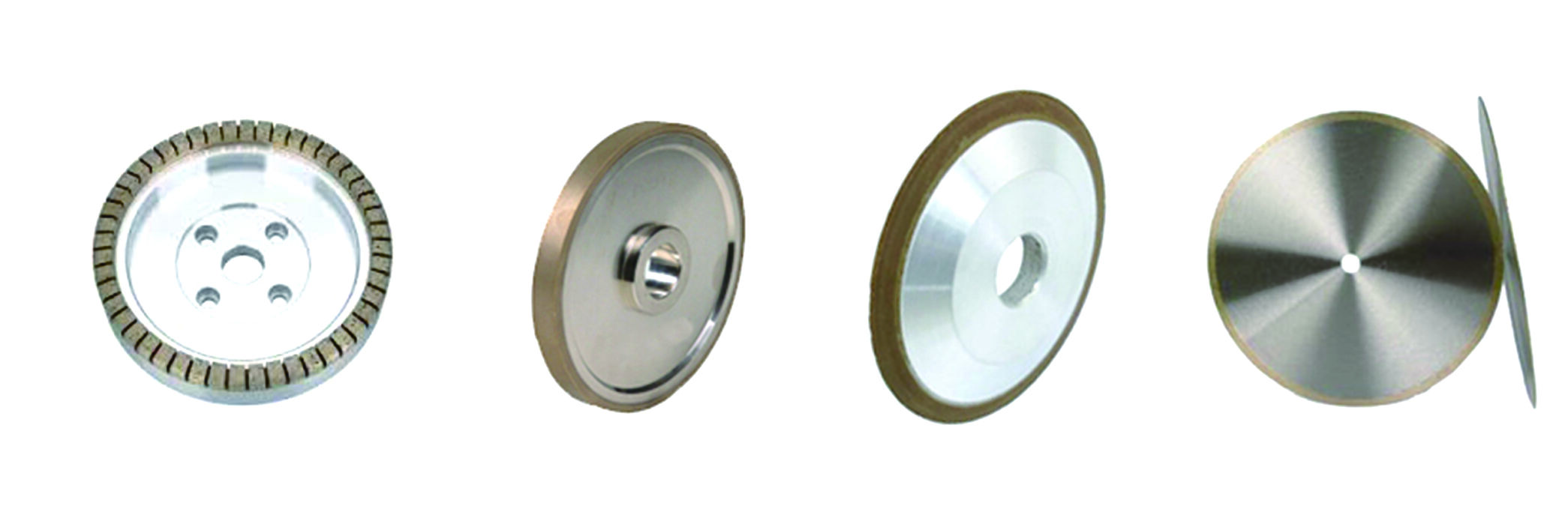

2.Metal Bond Diamond Grinding Wheels for Glass edge grinding

3.Metal Bond Diavmond Grinding Wheels for stone profile grinding

4.Metal Bond Diamond Mounted Point

5.Metal Bond Diamond Drills

Quick Detail:

1.Metal Bond Diamond Dressing Wheels and Tools

2.Metal Bond Diamond Grinding Wheels for Glass edge grinding

3.Metal Bond Diavmond Grinding Wheels for stone profile grinding

4.Metal Bond Diamond Mounted Point

5.Metal Bond Diamond Drills

Description:

The metal bonded diamond grinding wheel is a high-performance grinding tool. Its main feature is that it uses diamond particles as abrasive particles and metal powder (such as nickel, cobalt, iron, etc.) as a bonding agent, and is sintered under high temperature and high pressure. This type of grinding wheel is favored for its excellent wear resistance, high temperature stability and cutting efficiency.

Metal Bond Diamond Grinding Wheels is usually for stone and glass grinding. RZ designs diamond wheels with metal bond with features of long life, and minimum edge breaking on your products.

Also because of the super form holding features, metal bond diamond tool is ideal for making dressing tools. Metal Bond Sintered Diamond dressing roll is the best choice for traditional abrasive wheels forming. RZ can design the diamond dressing rolls for CNC on-line dressing and also for universal grinding machines.

Aerospace Field: used to process high-precision parts such as aerospace engine parts and aerospace devices.

Automobile Manufacturing Industry: used for precision grinding of key components such as automobile engines, gearboxes, and transmission devices.

Glass Processing: used for precision cutting and grinding of hard and brittle materials such as glass and ceramics.

| Parameters | |||||

| D | T | H | X | ||

| (mm) | Inch | (mm) | inch | ||

| 100 | 4" | 5-25.4 | 0.2-1" | TO YOUR REQUEST | 3-12mm |

| 150 | 6" | 5-25.4 | 0.2-1" | 3-12mm | |

| 175 | 7" | 5-25.4 | 0.2-1" | 3-16mm | |

| 200 | 8" | 5-50.8 | 0.2-2" | 3-16mm | |

| 250 | 10" | 5-50.8 | 0.2-2" | 3-20mm | |

| 300 | 12" | 10-50.8 | 0.4-2" | 3-20mm | |

| 350 | 14" | 10-50.8 | 0.4-2" | 3-20mm | |

| 400 | 16" | 10-50.8 | 0.4-2" | 3-20mm | |

| 450 | 18" | 10-50.8 | 0.4-2" | 5-20mm | |

| 500 | 20" | 16-50.8 | 0.6-2" | 10-20mm | |

| 600 | 24" | 16-50.8 | 0.6-2" | 10-20mm | |

Competitive Advantage:

Long wheel life

Superior form holding

Excellent for interrupted cuts

Retain shape and size during extreme grinding

Copyright © Zhengzhou Ruizuan Diamond Tool Co.,Ltd. All Rights Reserved — Privacy Policy