REZZ can provide :

* Continuo us generative grinding wheel(worm grinding wheel)

us generative grinding wheel(worm grinding wheel)

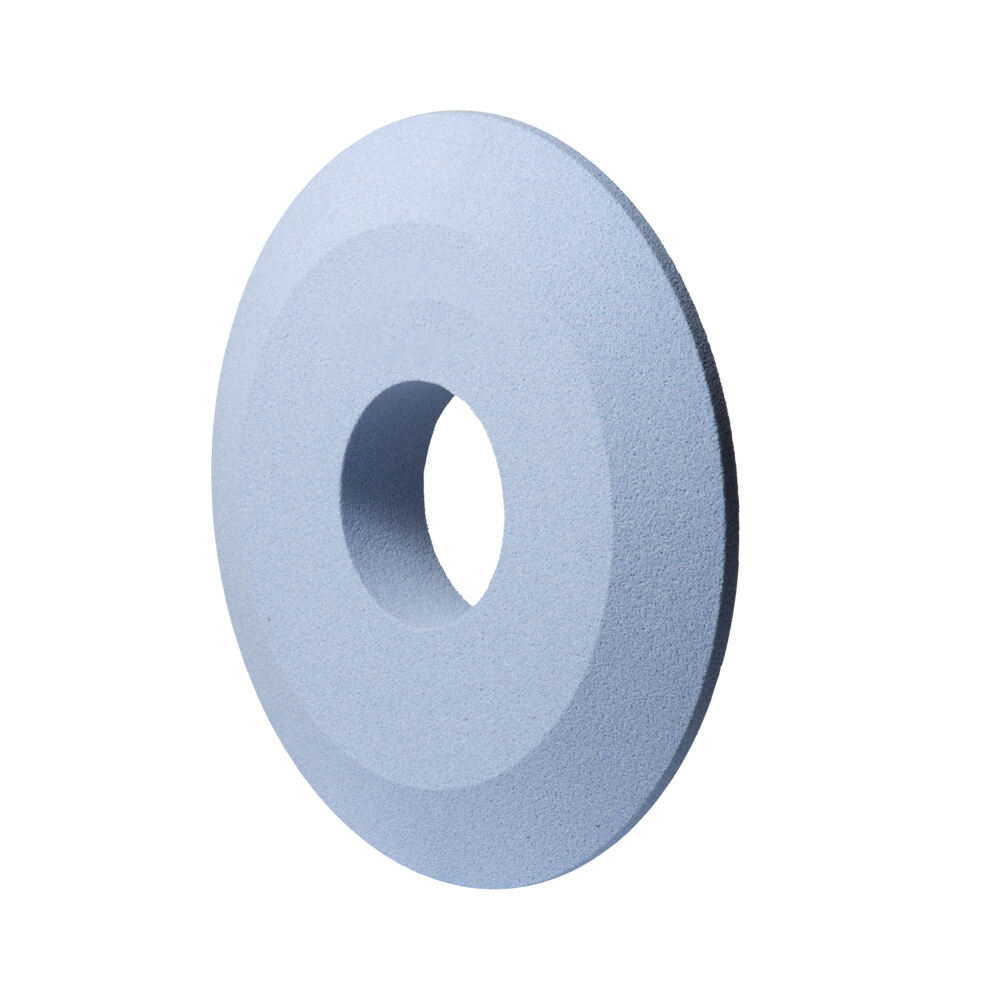

* Profile grinding wheel

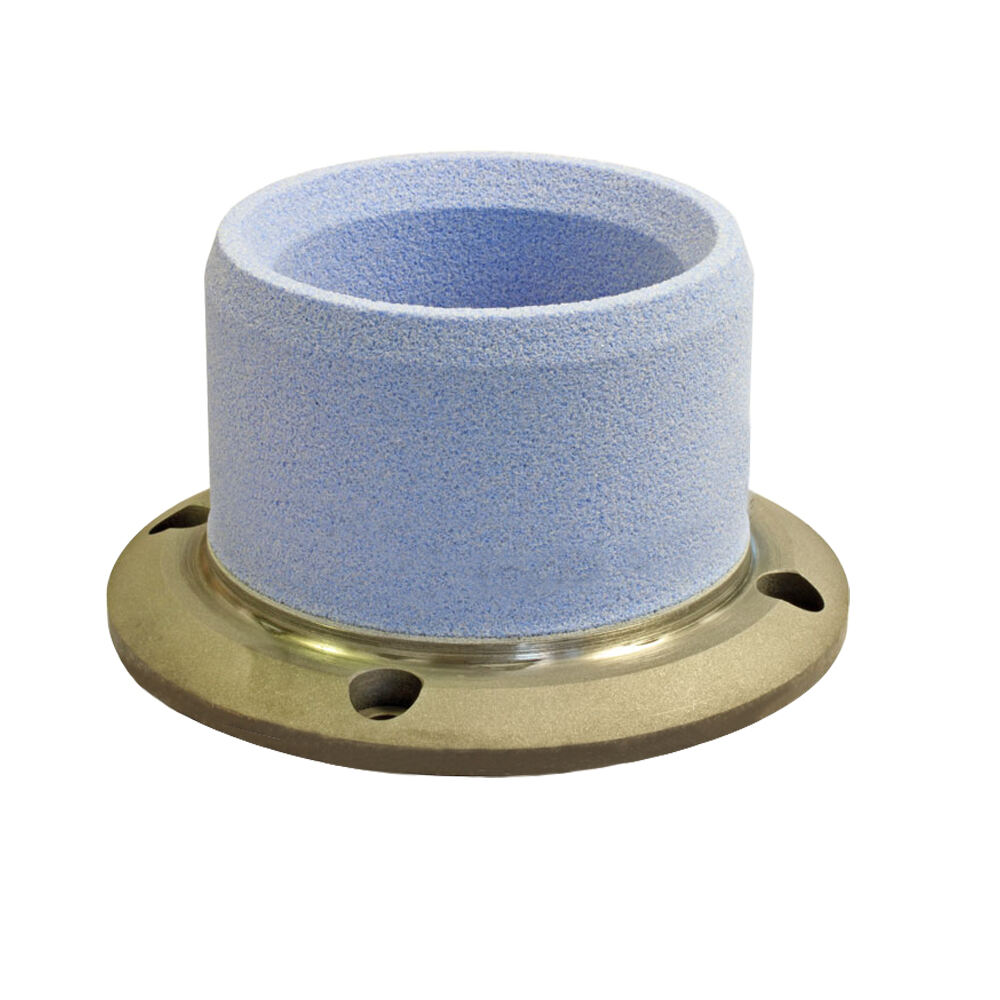

* Bevel gear grinding wheel

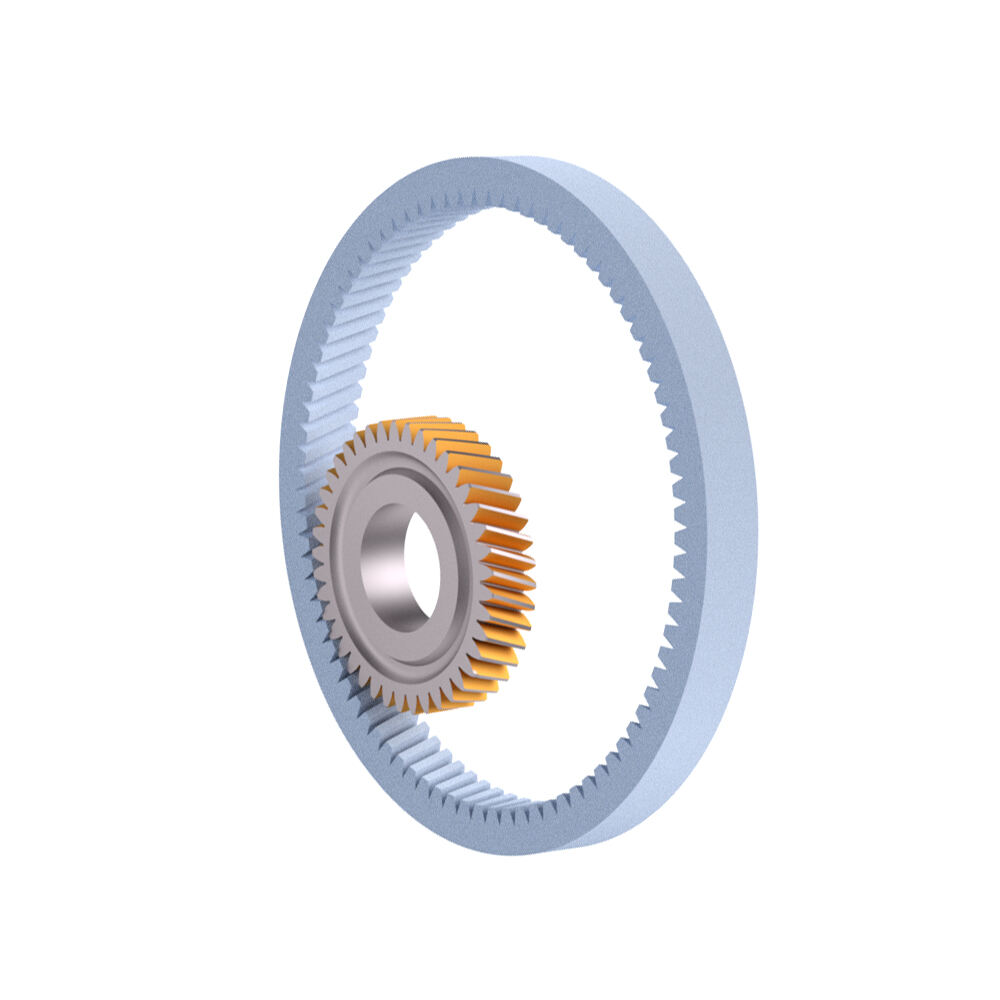

* Ceramic honing rings for tooth flank

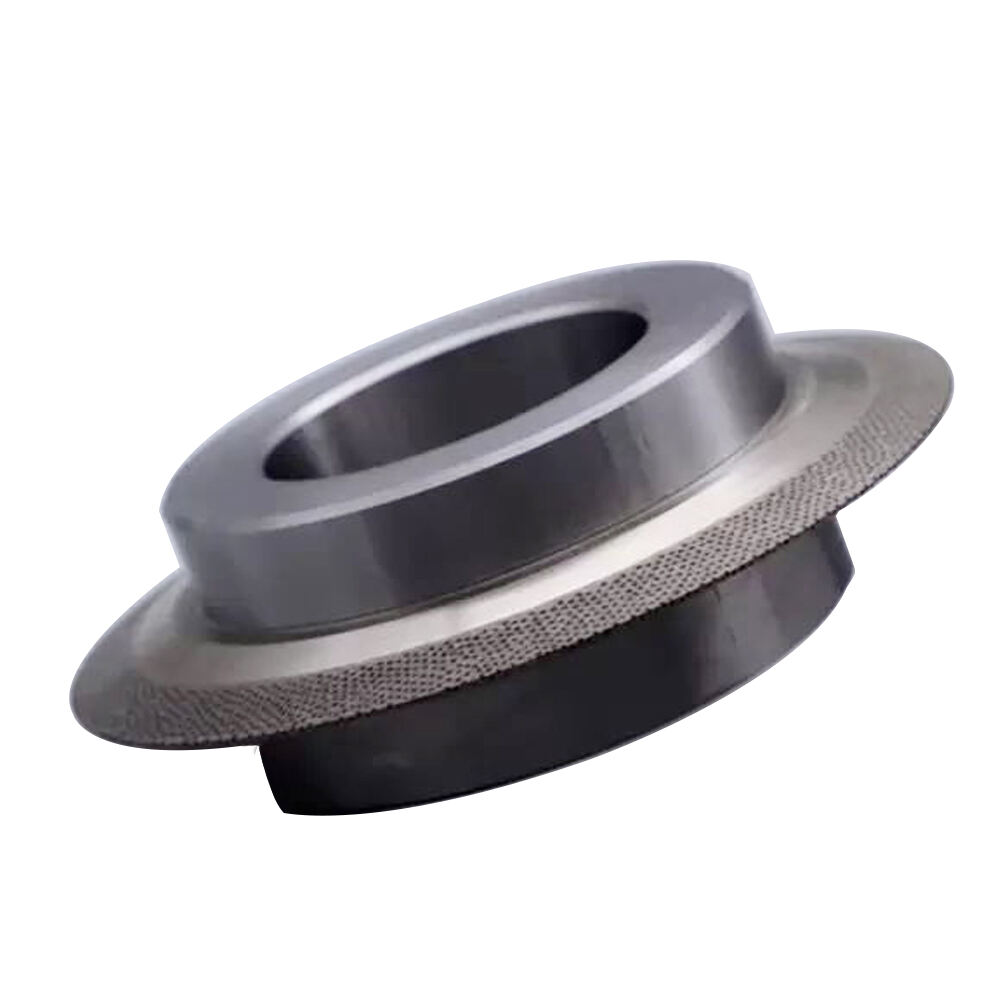

* Diamond dressing tools for gear grinding wheel

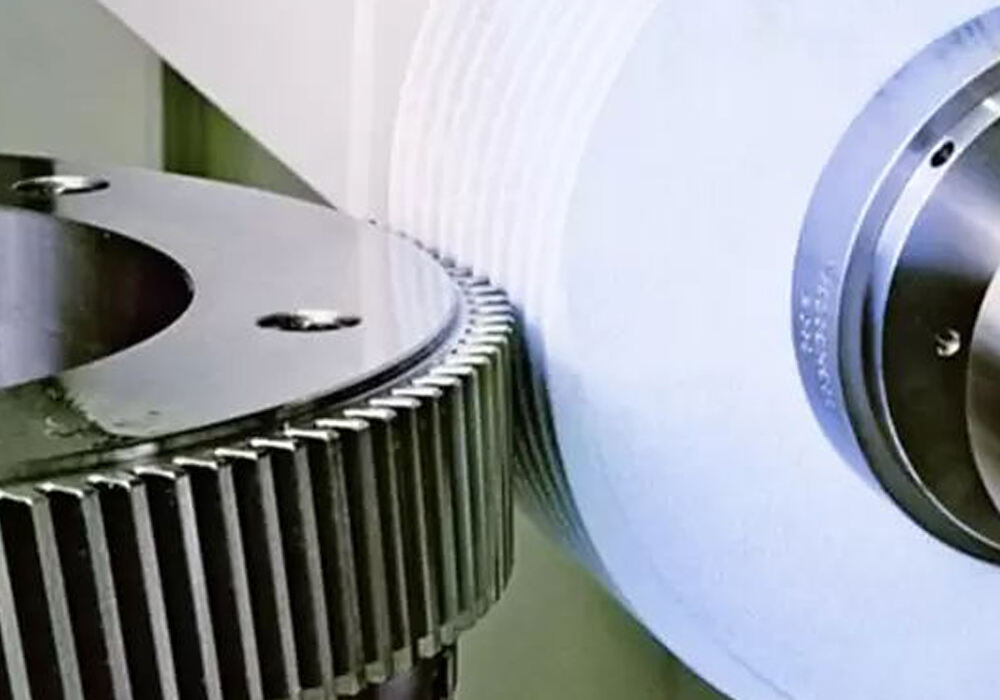

Detail:After gears are manufactured, they still need to be finished to improve surface finish and dimensional accuracy. Precision grinding gears provide excellent meshing and smooth operation due to the precise gear geometry of the gears.

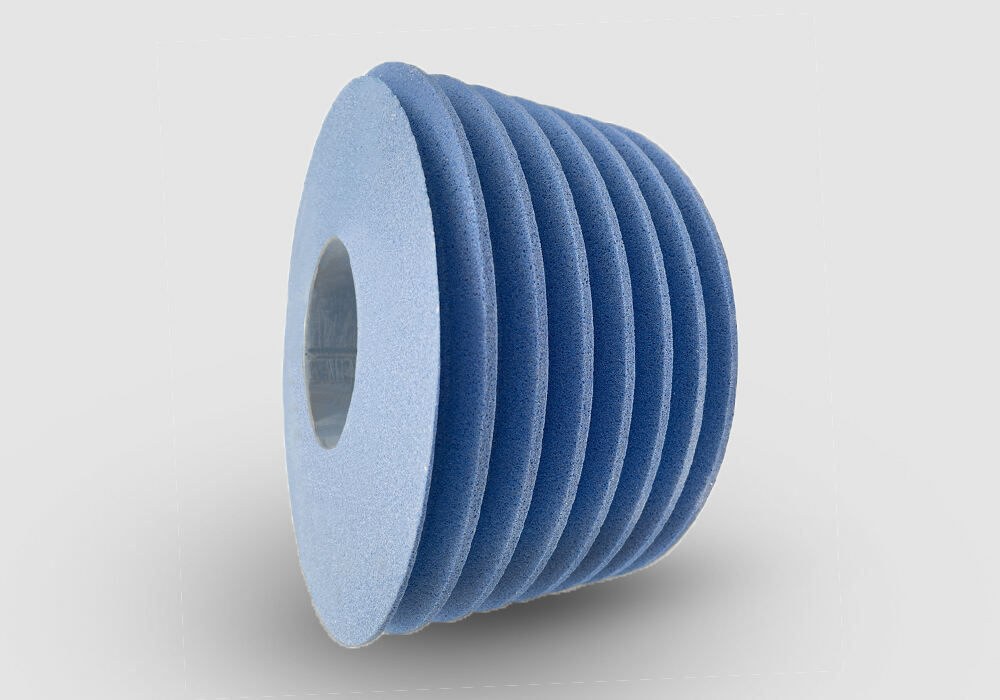

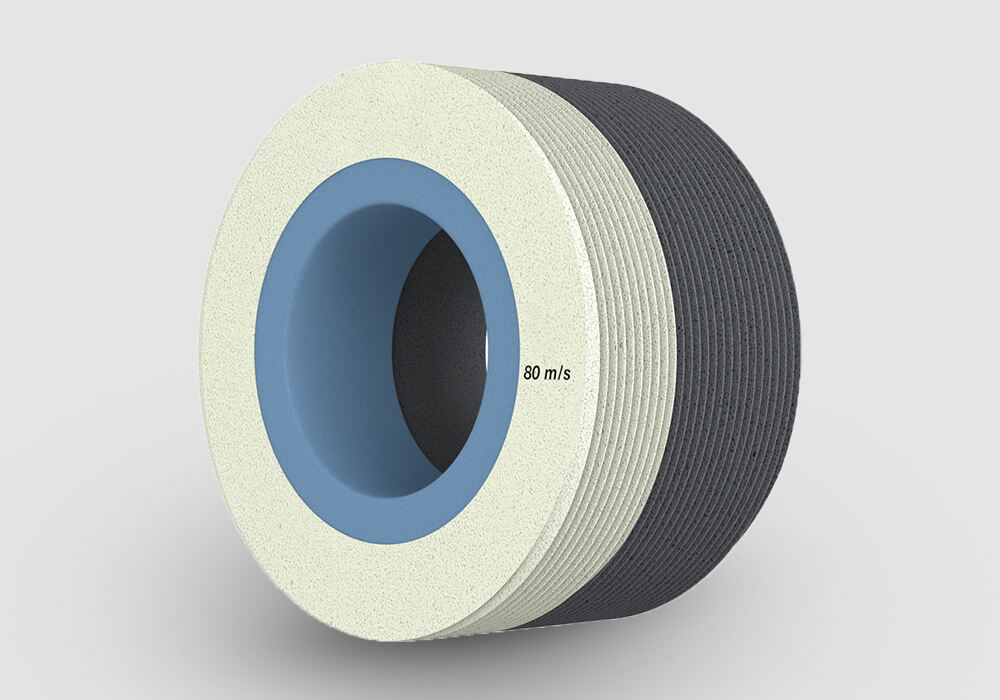

Description:About Worm grinding wheelThe worm grinding wheel has a high speed and continuous grinding, so the production efficiency is very high. The grinding accuracy is generally grade 5, up to grade 3, which is very suitable for the finishing of gears produced in large and medium batches. The continuous worm grinding wheel is mainly used for grinding the worm gear and worm gear surface of the reducer, so it is widely used for grinding of small and medium size gear, especially the grinding of mass gear. We have dual-worm grinding wheels and single worm wheels to choose from, Ruizuan worm grinding wheel adopts high-performance ceramic abrasives, which can effectively reduce the grinding force and improve the surface quality.

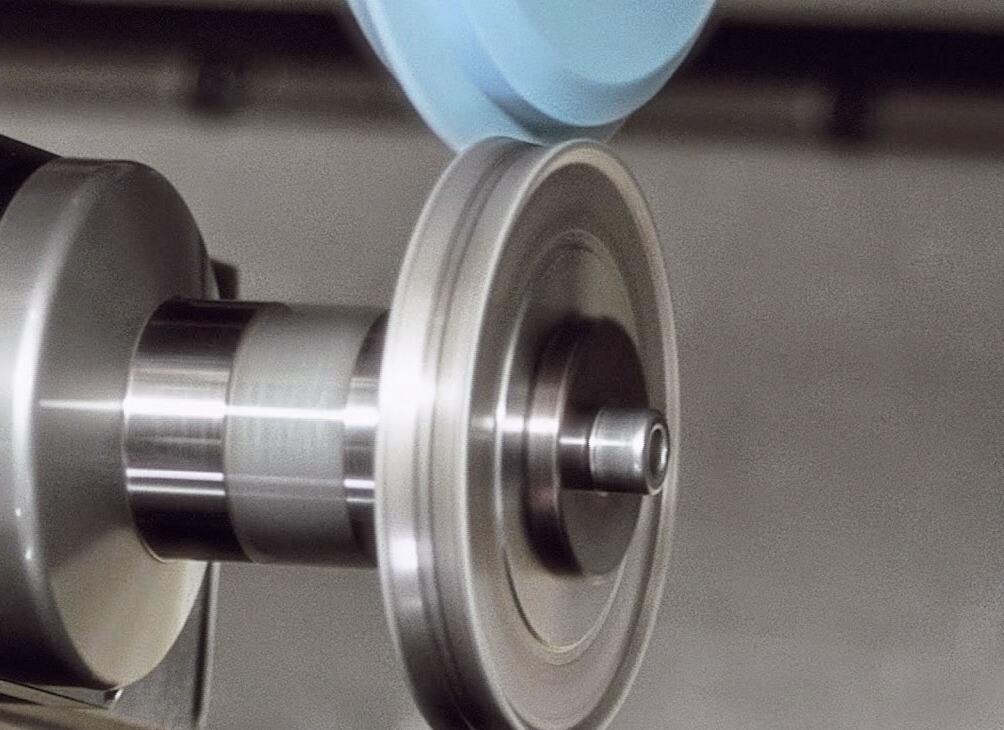

Flexible Dressing of Worm Grinding Wheel

The dressing of the worm grinding wheel is mostly done by flexible CNC dressing rollers. Ruizuan adopts CVD structure technology to design rollers with small arc radius, which can repair the required shape on the worm grinding wheel with high precision and minimum modulus.

Advantages of diamond rotary dresser:

* Achieve the optimal gear profile

* High profile accuracy

* High tooth shape retention ability

Application of diamond rotary dresser:

Diamond roller dressers are used for forming and dressing conventional abrasive grinding wheels and CBN wheels.

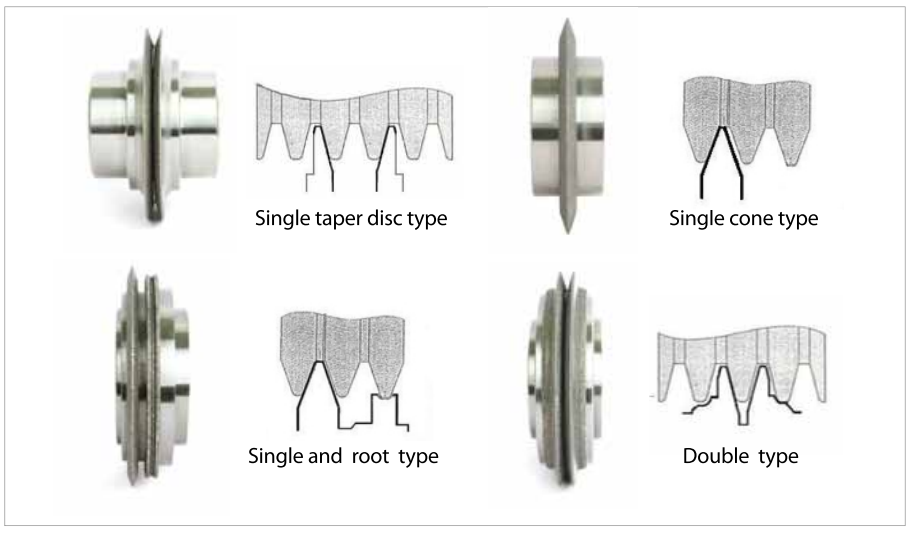

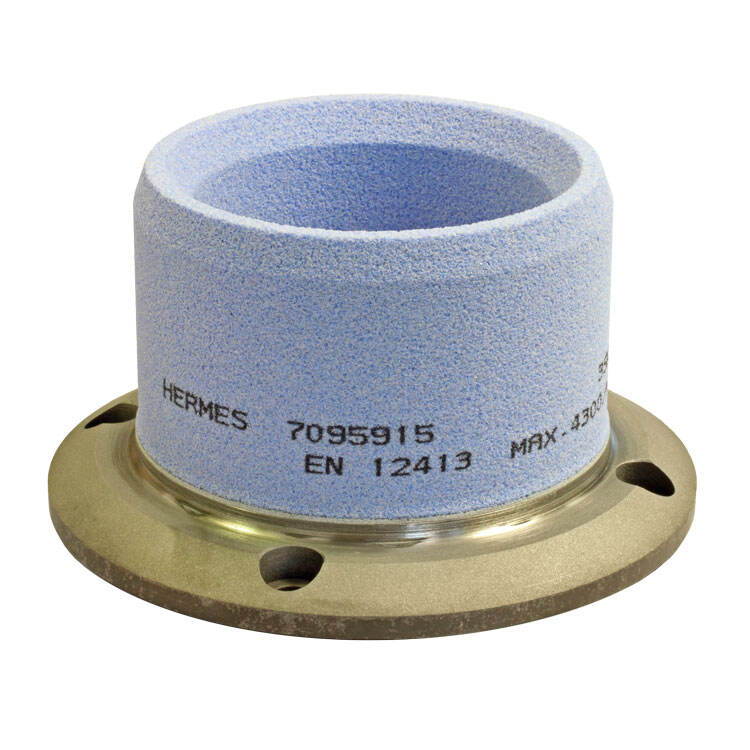

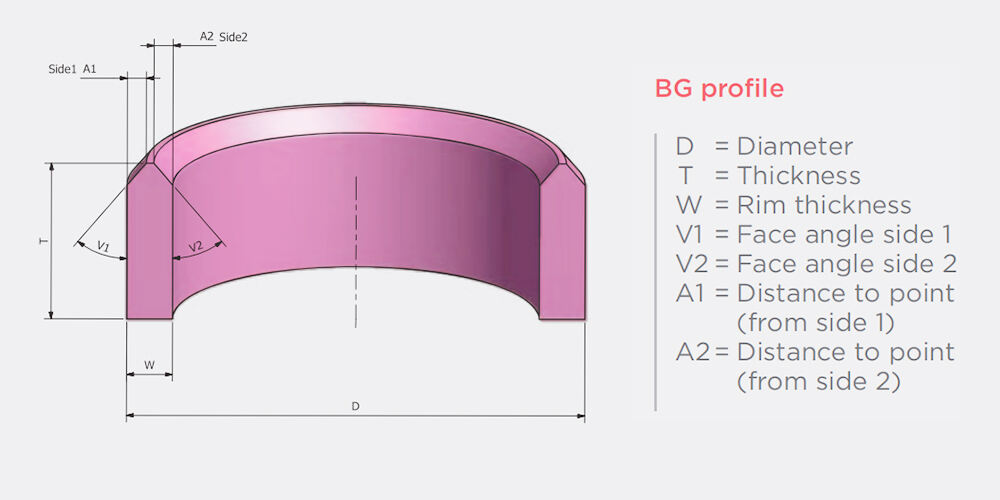

About Bevel Gear grinding wheel

RUIZUAN High production bevel gear grinding wheel,can effectively reduce gear surface roughness, correct tooth surface curvature, correct contact area, so as to improve meshing transmission. The profile modification of grinding wheel before grinding directly determines the profile of tooth surface after grinding. We have two options, with and without mounting plates. They are available in different materials and can be customized in size, granularity, etc..

Machines:

Klingelnberg, Gleason, Dr. Wiener,…

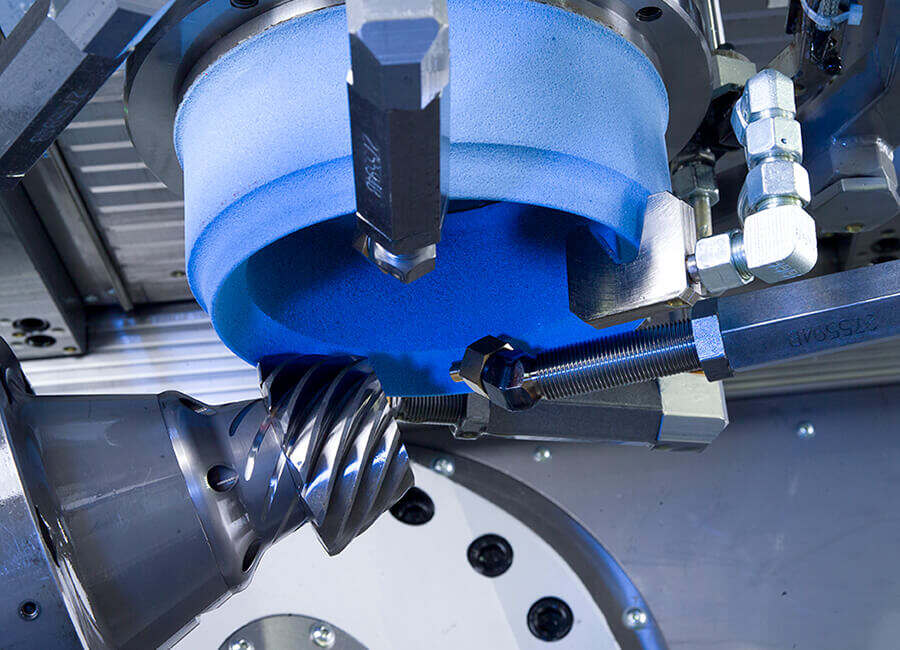

About profile grinding wheelGear profile grinding is a discontinuous grinding process. Contrary to generation grinding, in profile grinding gap by gap is machined. The grinding wheel profile is absolutely identical with the finished gear profile. The Innovative technology by ruizuan using high-performance ceramic abrasives with the newdeveloped bonding system was especially designed for the Single Rib Grinding application.The Single Rib Gear Grinding uses a flexible technique where each tooth flank is ground individually.

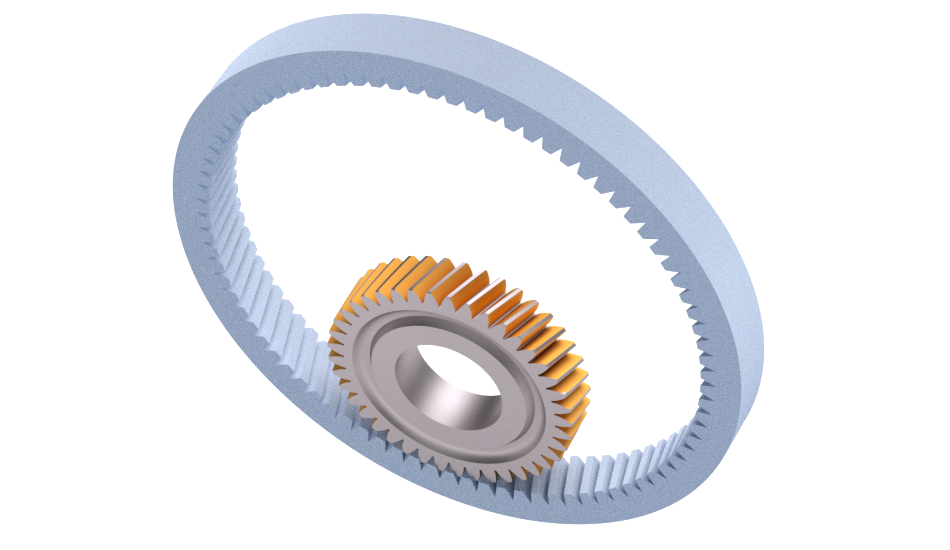

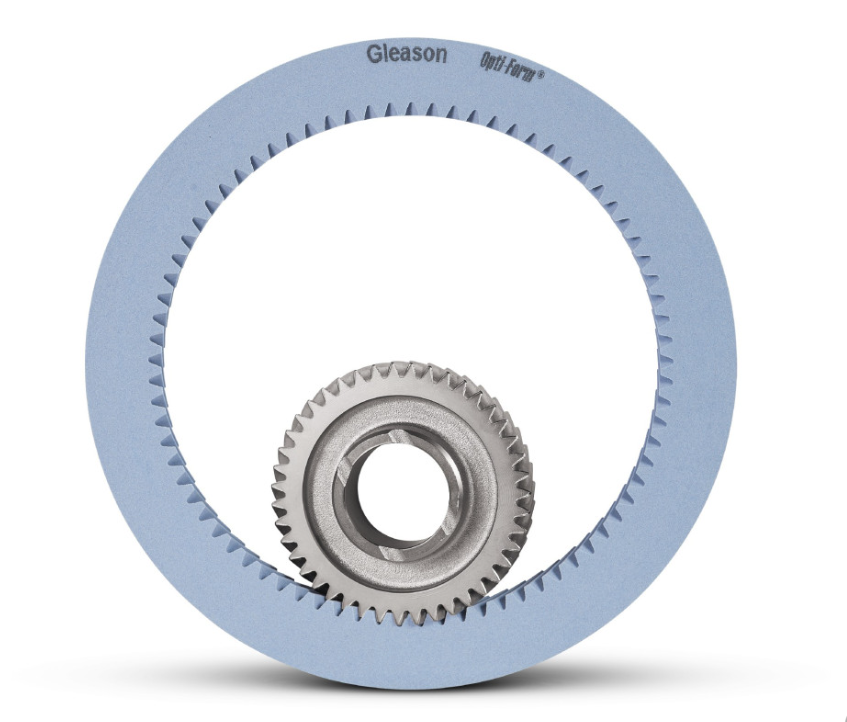

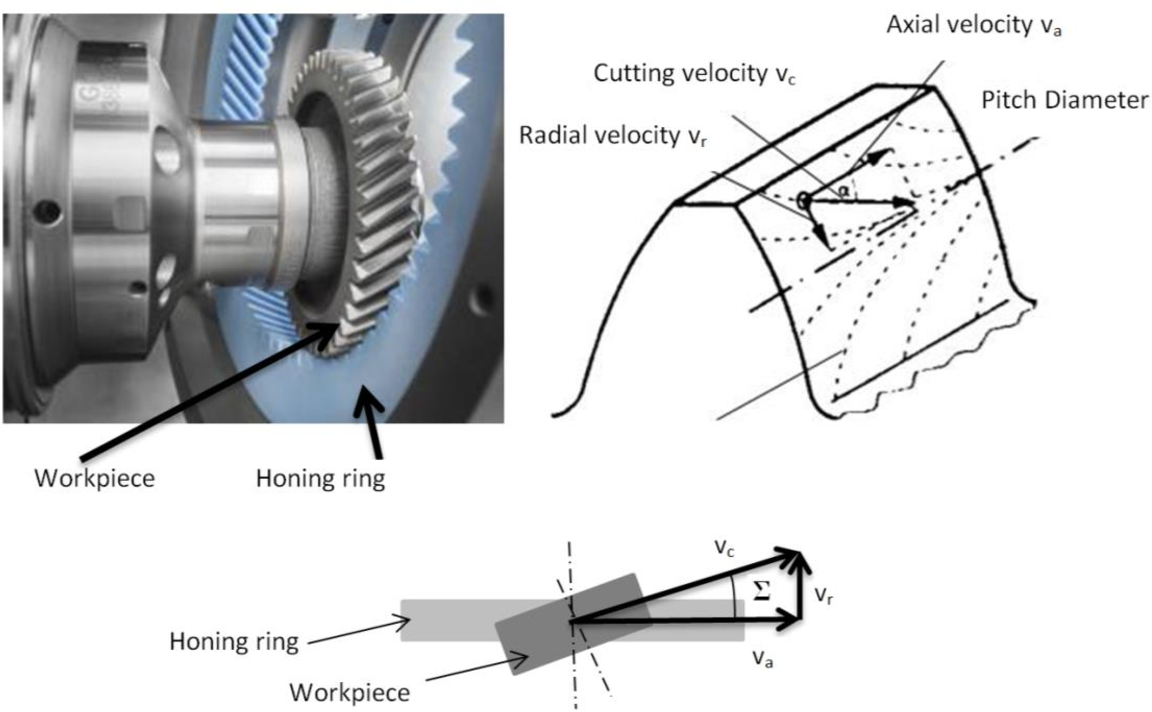

Ceramic honing rings for tooth flank honing

Gear honing is a continuous precision machining process in which the honing tool and workpiece are rolled off each other. Gear honing is to reduce noise in the transmission by changing the surface structure of tooth flanks.

Moresuperhard ceramic honing rings can correction of distortion due to the hardening process, and extended workpiece life.

Copyright © Zhengzhou Ruizuan Diamond Tool Co.,Ltd. All Rights Reserved — Privacy Policy