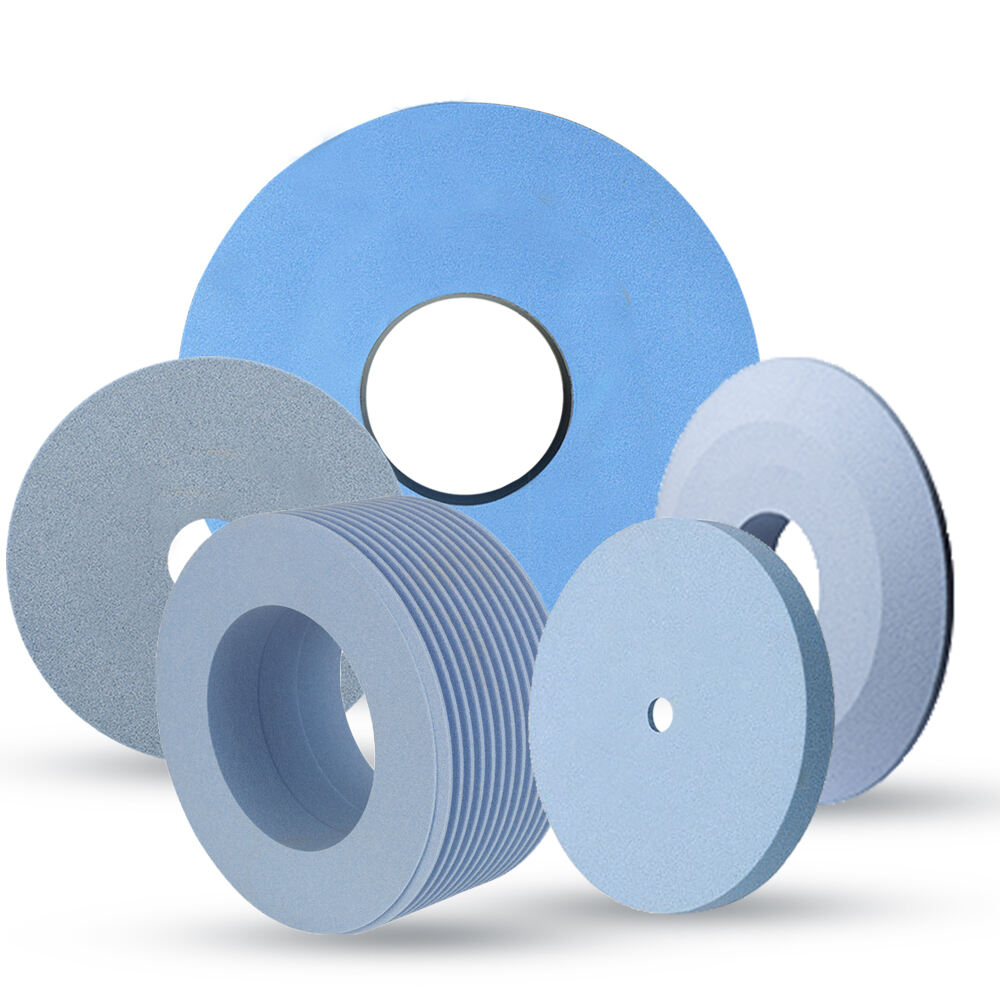

SG grinding wheel for Internal Grinding Roller Bearings, Crankshaft and Camshaft grinding, Gear Grinding

Description:

SG abrasive is a polycrystalline alumina abrasive with a submicron crystalline structure. It gives higher grinding performance than the conventional fused alumina abrasives. Grinding wheel made of ceramic abrasive with has a higher durability and longer life, which is 5-10 times than the grinding wheel made of common corundum, and its self-sharpening abrasive maximizes sharp edges on tools and dies.

The parameters of Ceramic abrasives :

| Main chemical composition | Physical properties | The offerable grain size | code |

| (typical value) | (grain size 60) | ||

| Al2O3 (99.22%) | Density : 3.90(g/cm³) | 24-180# | s |

| Na2O(0.08%) | Bulk density : 1.82(g/cm³) | ||

| Crystal size : 0.15 (μm) |

Applications of SG grinding wheel :

* Precision grinding for unhardened and hardened steels,such as cast iron,carbon steels, alloy steels, and tool steels, etc.

* Internal grinding roller bearings, cylinders, compressor parts,gear parts, hydraulic and pneumatic cylinders etc.

* Grinding the crankshaft and camshaft of the engine and transmission of the car ; worm gear grinding.

Advantages of SG grinding wheel:

* Grinding wheel made of ceramic abrasive with has a higher durability and longer life, which is 5-10 times than the grinding wheel made of common corundum.

* Sharp grains , good cutting ability, and high grinding efficiency .

* Good self- sharp ability, microcrystalline structure Benefits .

* Very good cutting capability, sharp grains .

* High removal rate extended wheel life .

Copyright © Zhengzhou Ruizuan Diamond Tool Co.,Ltd. All Rights Reserved — Privacy Policy