Ruizuan have rich experience on providing solutions for semiconductor industry from silicon ingot cutting, slicing to final wafer product, we can provide:

* Diamond cutting blade for ingot

* Cylindrical grinding wheel for ingot

* Double disc grinding wheel for lapping wafer

* Metal diamond edge grinding wheel for chamfering wafer dge

* Polishing pad and polishing fluid for CMP polishing

* Back grinding wheel for wafer thinning

* Diamond hub-less /hub dicing blade

Description:

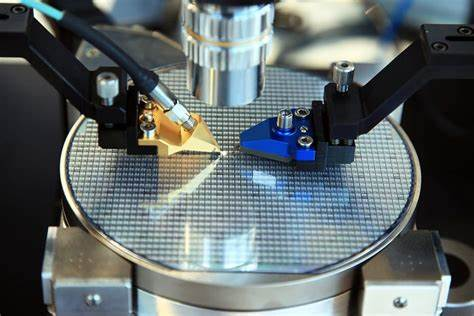

![OIP[1]](https://shopcdnpro.grainajz.com/663/upload/product/e49eceddf073e8e67abfac2e235b94ba7d048f27da3d2a9cfdf0853473fede86.jpg)

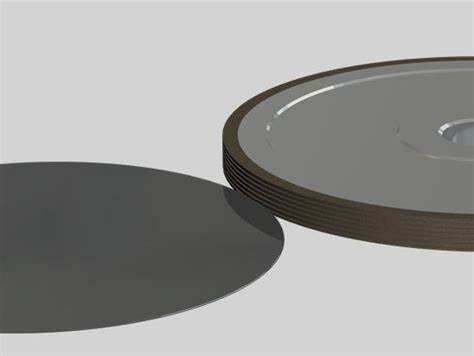

We designed series of diiamond grinding wheels for semi-condutor industries & Photovoltaic Industry. They include Thinner Grinding Wheels, Dicing Blades, Precision Cutting Wheels and diamond wires. The workpieces are silicon wafers, monocrystalline silicon, Package Singulation, synthetic sapphiers, Alumina ceramics、EMC、PCB. The processing methods are back thinning, rough & fine grinding, edge grinding, dicing, and precision cuttting. Our diamond wheels are performing well on wear resistance, quality consistency and economically cost-effective.

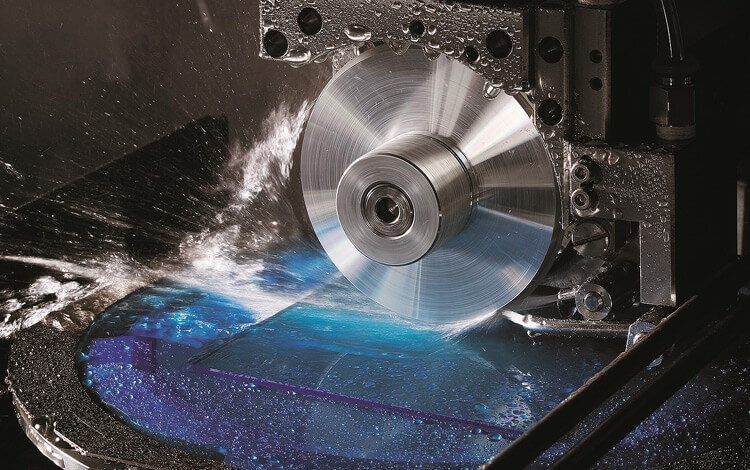

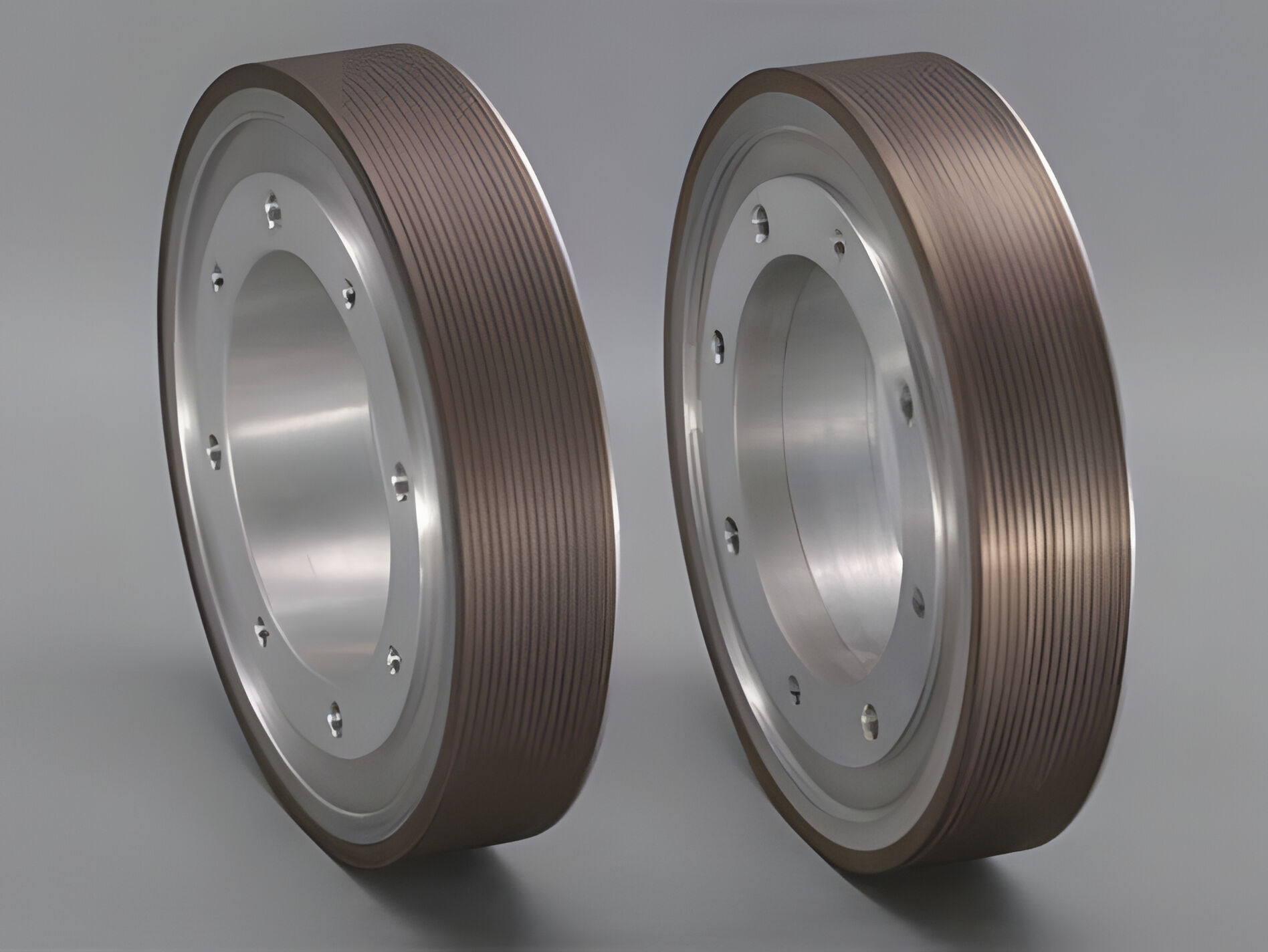

Semiconductor Thinner Grinding Wheel

Back grinding wheels are mainly used for the thinning andfine grinding of the silicon wafer. These products producedby our institute which possess superior grinding performanceand high cost.

performance are among the top level worldwide. They canbe used with the Japanese, German, American, Korean andChinese grinders.

| Model | Dmm) | T (mm) | H (mm) |

|

6A2/6A2H |

175 | 30, 35 | 76 |

| 200 | 35 | 76 | |

| 350 | 45 | 127 | |

|

6A2T |

195 | 22.5, 25 | 170 |

| 280 | 30 | 228.6 | |

|

6A2T(three ellipses) |

350 | 35 | 235 |

| 209 | 22.5 | 158 | |

| Other specifications can be produced according to customers’ requirement. | |||

Wafer Dicing Blades

With electro plated nickel bond,ultrathin hub blades can provide stable dicing performance of narrow street wafers.

| Exposure(μm) | 380 | 510 | 640 | 760 | 890 | 1020 | 1150 | 1270 | Grit Size |

| Kerf width(μm) | 380-510 | 510-640 | 640-760 | 760-890 | 890-1020 | 1020-1150 | 1150-1270 | 1270-1400 | #5000 #4800 #4500 #4000 #3500 #3000 #2500 #2000 #1800 #1700 #1500 |

| 16-20 | 20*380 | 20*510 | |||||||

| 21-25 | 25*380 | 25*510 | 25*640 | ||||||

| 26-30 | 30*380 | 30*510 | 30*640 | 30*760 | 30*890 | 20*1020 | |||

| 31-35 | 35*380 | 35*510 | 35*640 | 35*760 | 35*890 | 35*1020 | |||

| 36-40 | 40*380 | 40*510 | 40*640 | 40*760 | 40*890 | 40*1020 | 40*1150 | ||

| 41-50 | 50*380 | 50*510 | 50*640 | 50*760 | 50*890 | 50*1020 | 50*1150 | ||

| 51-60 | 60*510 | 60*640 | 60*760 | 60*890 | 60*1020 | 60*1150 | 60*1270 | ||

| 61-70 | 70*640 | 70*760 | 70*890 | 70*1020 | 70*1150 | 70*1270 | |||

| 71-80 | 80*890 | 80*1020 | 80*1150 | 80*1270 | |||||

| 81-90 | 90*1020 | 90*1150 | 90*1270 | ||||||

| Special size can be designed according to customers’ requirement | |||||||||

Diamond cutting grinding wheel

Diamond cutting grinding wheel: mainly used for ceramics, crystal, quartz, gemstones, carbide,Grooving and cutting of hard and brittle materials such as magnetic materials, electro-optical glass tubes, and optical glass.

| D (mm) | T | Grit | bonded | Groove |

| 50 – 250 | 3 – 20 | 325 – 3000# | Metal / resin | 1-10G |

| Other size can be designed according to customers’ requirement | ||||

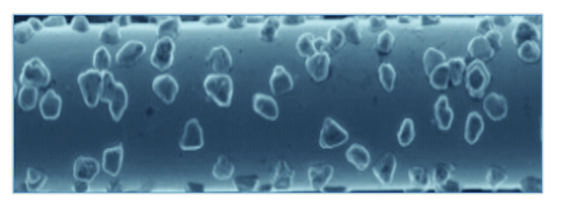

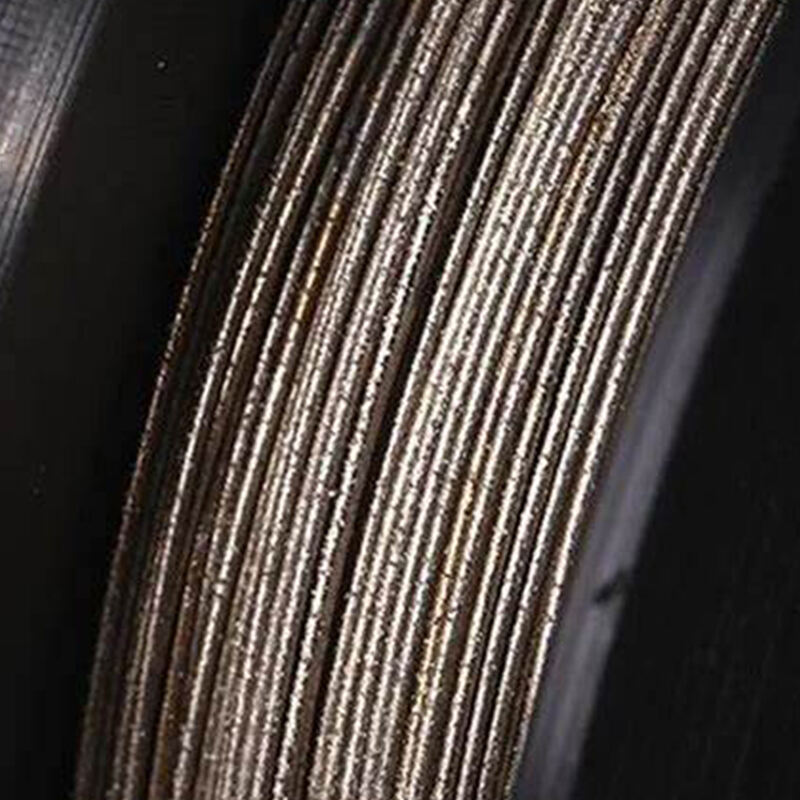

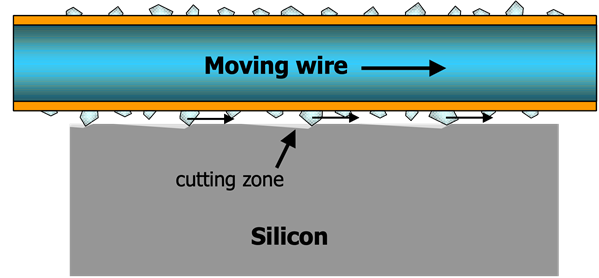

Diamond Wires

RZ Diamond wires uses nickel electroplating to coat diamond particles on the surface of ultra-fine steel wires,mainly used for crystal silicon cutting.

We use high strength steel wire as Mother Wire, adopt entire process quality control and automatic electroplating technology. It keeps good distribution of diamond grits, consistency of diamond layer and strong grit holding ability.

Copyright © Zhengzhou Ruizuan Diamond Tool Co.,Ltd. All Rights Reserved — Privacy Policy