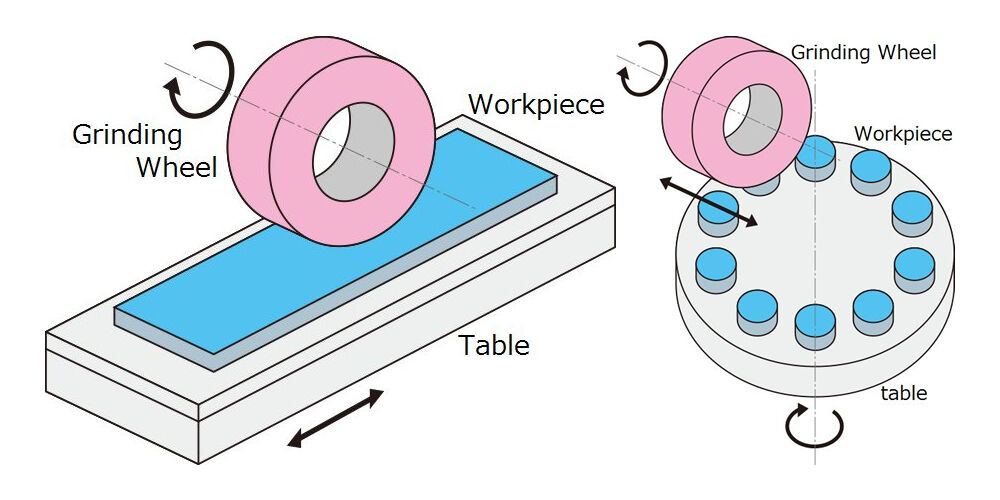

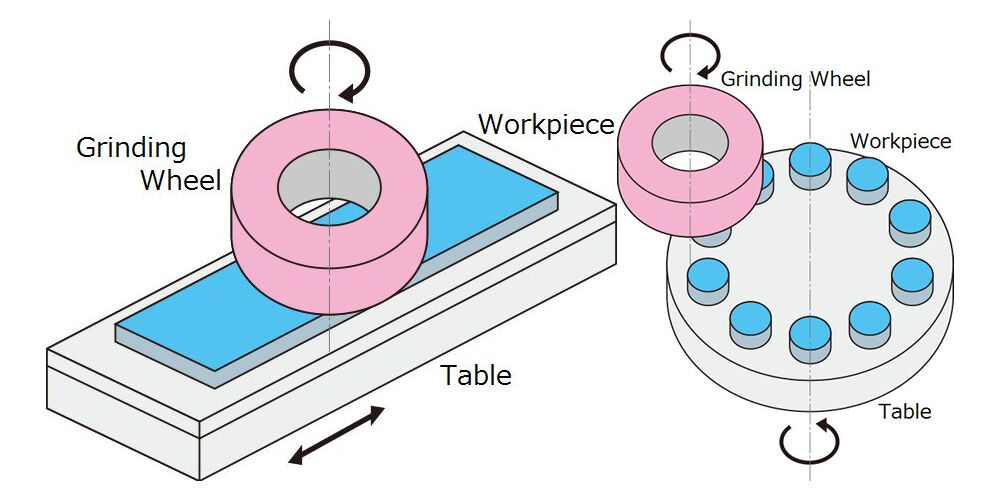

Surface grinding is used for grinding planes, grooves, etc. on surface grinders. The workpiece is rotatably ground with a grinding wheel to achieve the required flatness.

Description:

Surface grinding methods include

-Horizontal-spindle,

-Vertical-spindle,

-Vertical-spindle rotary grinding,

-Horizontal spindle single disk, and vertical swivel head grinding.

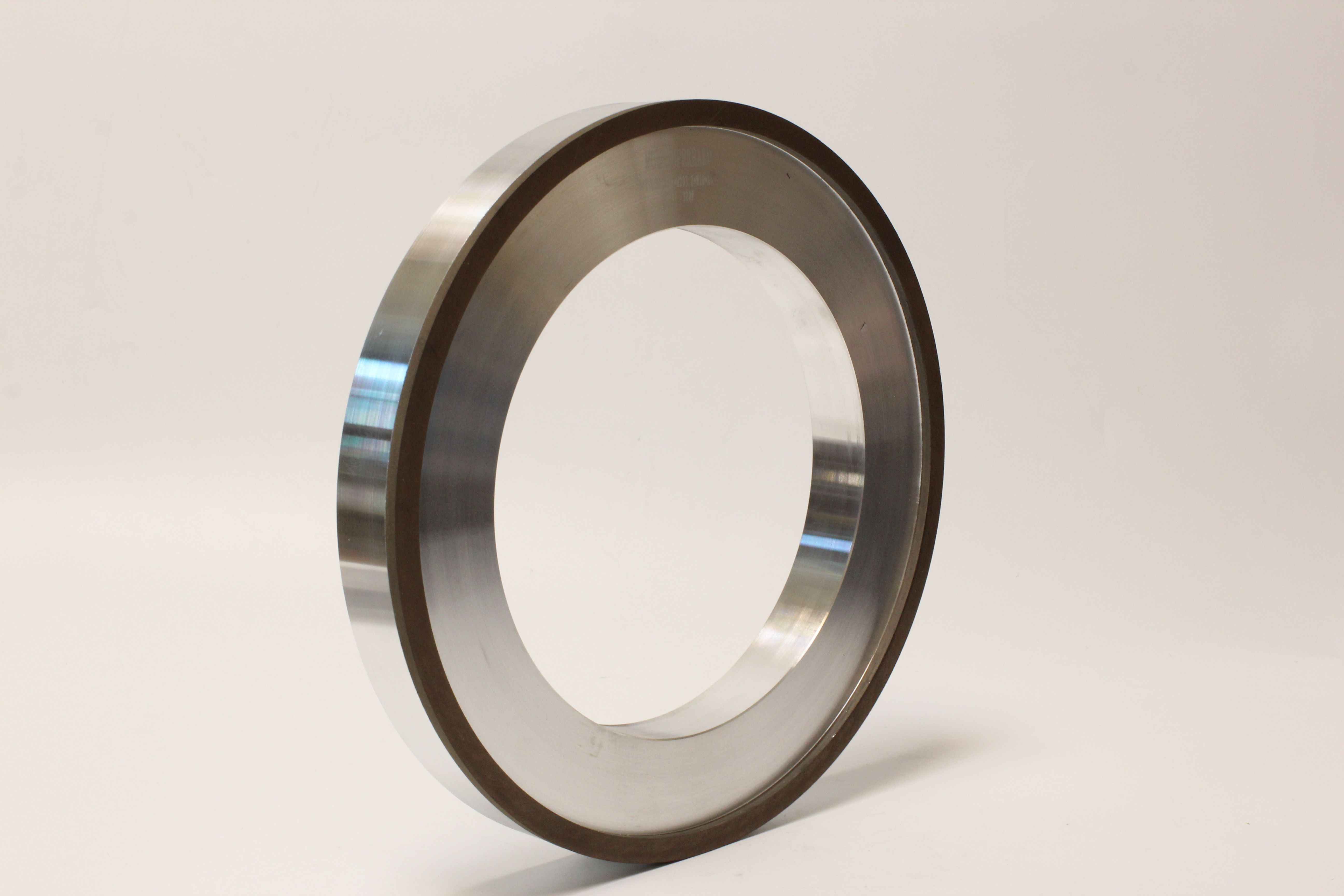

Diamond Face Grinding wheels for circular saw blades

RZ provides Diamond and CBN surface grinding wheels to the saw blade industry. Widely used for for linear reciprocating motion grinding of the cutting face and of the back side of the circular saw blades.

Advantages of resin diamond face grinding wheel

1.Excellent performance ratio

2.High material removal rates

3.Long lifespan

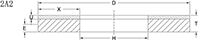

SPECIFICATION

| Shape | D (mm) | W (mm) | X(mm) | H(mm) | T(mm) | S |

|

4A2 |

125 | 4 | 2 | 20 | 9 | 15° |

| 125 | 4 | 3 | 20 | 10 | 15° | |

| 125 | 4 | 4 | 20 | 11 | 15° | |

| 125 | 5 | 2 | 20 | 9 | 15° | |

| 125 | 5 | 3 | 20 | 10 | 15° | |

| 125 | 5 | 4 | 20 | 11 | 15° | |

| 150 | 4 | 2 | 20 | 11 | 15° | |

| 150 | 4 | 3 | 20 | 12 | 15° | |

| 150 | 4 | 4 | 20 | 13 | 15° | |

| 150 | 5 | 2 | 20 | 11 | 15° | |

| 150 | 5 | 3 | 20 | 12 | 15° | |

| 150 | 5 | 4 | 20 | 13 | 15° | |

| 200 | 4 | 1.5 | 20 | 15 | 15° | |

| * other size can be customized | ||||||

RZ resin bond diamond wheels on lathe or mounted separately for sharpening tungsten carbide coating, making your own spade drills, for resharpening tools.

The advantages of resin diamond grinding wheel for carbide coating

* The resin bonded diamond surface ensures that they are very hard wearing and leave a beautiful and accurate finish.

* A high concentration of diamond provides a quick cutting surface without vibration so you can spend more time working and less time sharpening.

* 3 grades (grain size ) of diamond wheels: coarse, medium and fine.

– The coarse grade is solely used for shaping hard materials and saves time when removing large stock amounts.

– The medium grade is our all purpose, most popular, diamond wheel and will put a great edge on a carbide graver as well as sharpen our carbide spade drills.

– Fine grade diamond wheel is used for finishing, this is not always necessary but the better the tool the better the finish on your work.

| Type | Diameter (inches) | D(mm) | H(mm) | X(mm) | T(mm) | U(mm) |

| 1A1 | 4” | 100 | 20 | 6 | 12 | |

| 1A1 | 100 | 20 | 10 | 10 | ||

| 1A1 | 100 | 20 | 10 | 12 | ||

| 1A1 | 100 | 25.4 | 10 | 20 | ||

| 1A1 | 8” | 200 | 76.2 | 10 | 25 | |

| 1A1 | 12” | 300 | 76.2 | 10 | 25 | |

| 1A1 | 300 | 127 | 10 | 25,30,40 | ||

| 1A1 | 300 | 127 | 25 | 50 | ||

| 14A1 | 300 | 127 | 6,10 | 40 | 10 | |

| 14A1 | 300 | 127 | 10 | 40 | 15 | |

| 1A1 | 16” | 400 | 127 | 10,25 | 25 | |

| 1A1 | 400 | 127 | 10 | 30,40,50 | ||

| 1A1 | 20” | 500 | 203 | 10 | 15,20 | |

| 1A1 | 500 | 254 | 38 | 25,50 | ||

| 1A1 | 24” | 600 | 254 | 25 | 25 | |

| 1A1 | 600 | 304.8 | 5 | 40 | ||

| 1A1 | 600 | 203 | 25 | 50 | ||

| 1A1 | 600 | 304.8 | 10 | 50 | ||

| 1A1 | 30” | 750 | 304.8 | 10 | 40,50 | |

| 1A1 | 35.4” | 900 | 304.8,305 | 10 | 50,75 | |

| 1A1 | 36” | 914.4 | 304.8,305 | 10 | 50.8 | |

| 1A1 | 43” | 1100 | 304.8 | 10 | 50 | |

| We can also customized according to your requirements. | ||||||

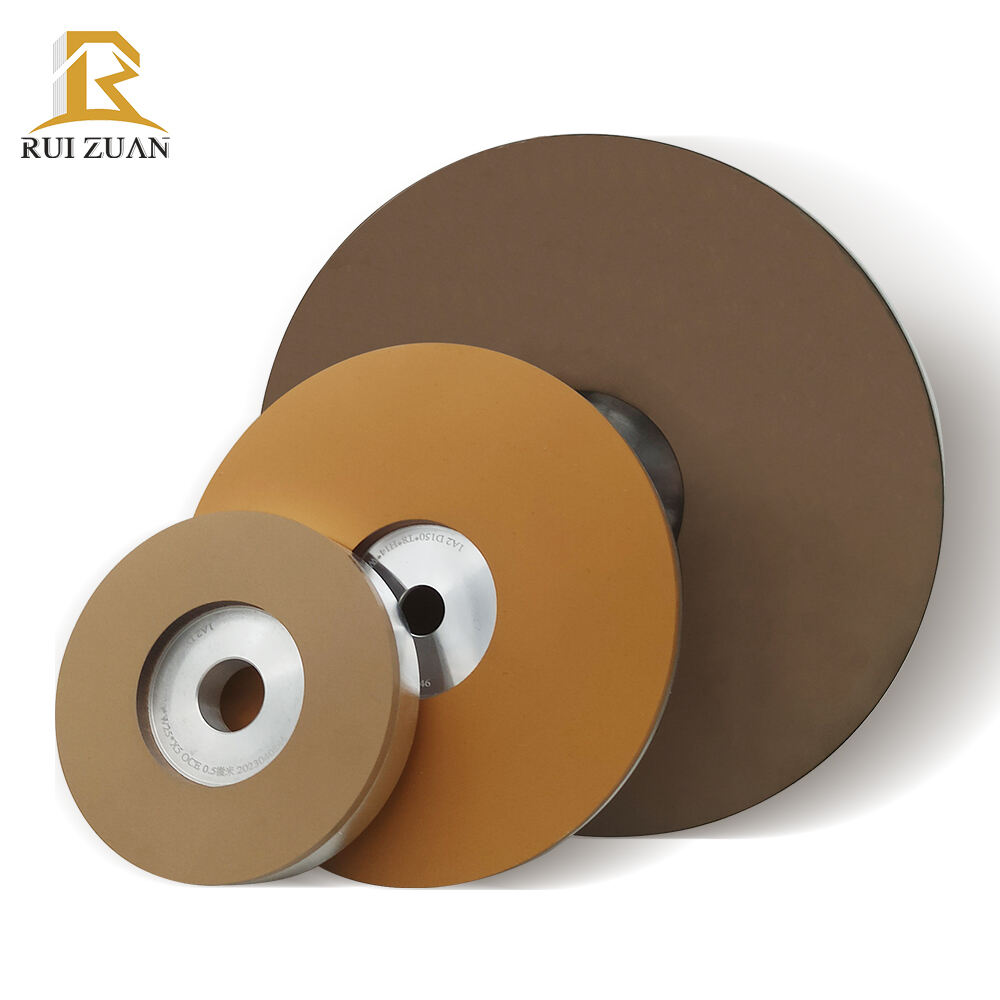

Resin Diamond Lapping Discs for Gemstone surface grinding

Diamond grinding discs, diamond lapping discs are used for polishing and faceting gemstones (jade, crystal, agate), spinel, sapphire, jewellery, glass artwork and precision machining industry.

Advantages:

Efficient batch double and single side grinding

High wear resistance and long working Life

High parallelism and flatness of workpiece

Good surface quality

| Model | Diameter |

|

6 inch (150mm) 8 inch (200mm) 14 inch (350mm) |

|

The range of diameter from Ф100~Ф1200mm Roughness: Ra 0.05μm~Ra0.02μm Planeness:<2μm |

|

| Other sizes diamond lapping disc can also be customized | |

Copyright © Zhengzhou Ruizuan Diamond Tool Co.,Ltd. All Rights Reserved — Privacy Policy