In the ever - evolving landscape of precision grinding, the choice of abrasive is pivotal. Ceramic - bonded CBN (Cubic Boron Nitride) abrasives have emerged as a game - changer, offering unique advantages over traditional abrasives and even their diamond - based counterparts. At Zhengzhou Ruizuan Diamond Tools, with our extensive expertise in abrasive manufacturing, we're here to shed light on the nuances of ceramic - bonded CBN, comparing it to diamond abrasives and common abrasives.

Understanding Ceramic - Bonded CBN Abrasives

CBN is a synthetic super - abrasive material, second only to diamond in hardness. Its unique crystal structure endows it with remarkable properties such as high thermal stability, excellent chemical inertness to iron - based materials, and superior wear resistance. When combined with a ceramic bond, these qualities are further enhanced.

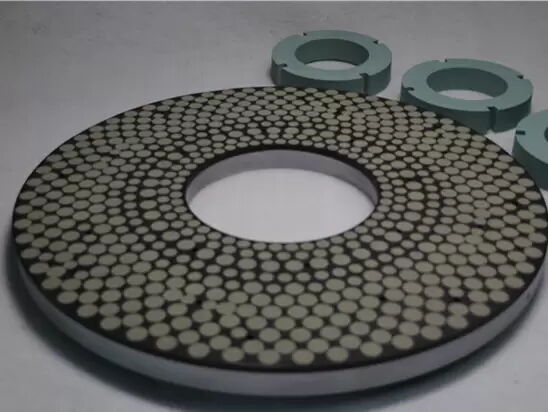

Ceramic bonds, made from materials like kaolin, feldspar, and glass frits (in our case, often synthetic recrystallized glasses), provide several key benefits. They offer high strength, ensuring the CBN grains are firmly held in place during grinding. The porous nature of ceramic bonds allows for efficient chip evacuation and coolant circulation, which is crucial for maintaining a cool and efficient grinding process. Additionally, ceramic bonds have good self - sharpening properties. As the wheel grinds, the bond gradually wears away, exposing fresh CBN grains, thus maintaining a consistent cutting action.

Vitrified- Bonded CBN vs. Diamond Abrasives

Chemical Reactivity

One of the most significant differences between ceramic - bonded CBN and diamond abrasives lies in their chemical reactivity. Diamond, an allotrope of carbon, is highly reactive with iron - based materials at elevated temperatures. When grinding steel or other ferrous alloys, diamond can undergo graphitization, where the carbon atoms in diamond rearrange into a graphite - like structure. This not only weakens the diamond grains but also reduces the effectiveness of the abrasive. In contrast, CBN is chemically inert to iron, making ceramic - bonded CBN an ideal choice for grinding ferrous materials. This property ensures that the CBN grains maintain their integrity and cutting ability throughout the grinding process, resulting in longer - lasting tools and better - quality finishes.

Thermal Stability

Diamond has a relatively lower thermal stability compared to CBN. While diamond can withstand temperatures up to around 800°C in an oxidizing environment, CBN can endure temperatures as high as 1250 - 1350°C. This makes ceramic - bonded CBN more suitable for high - speed and high - pressure grinding applications, where significant heat is generated. In such scenarios, diamond abrasives may degrade rapidly, leading to premature tool wear. For example, in the grinding of hardened steels in the automotive and aerospace industries, ceramic - bonded CBN wheels can maintain their performance under extreme thermal conditions, delivering consistent results.

Applications

Diamond abrasives are well - suited for grinding non - ferrous materials such as ceramics, glass, and carbide. Their extreme hardness allows for efficient material removal and the creation of fine surface finishes on these hard and brittle substances. However, when it comes to ferrous metals, ceramic - bonded CBN takes the lead. It is the go - to abrasive for grinding materials like high - speed steel, tool steel, and alloy steels. In the manufacturing of gears, shafts, and bearings in the automotive and machinery industries, ceramic - bonded CBN wheels are used to achieve tight tolerances and superior surface quality.

Vitrified - Bonded CBN vs. Conventional Abrasives

Hardness and Abrasive Power

Conventional abrasives like aluminum oxide and silicon carbide have significantly lower hardness compared to CBN. Aluminum oxide has a hardness of around 2000 - 2200 HV, while silicon carbide is in the range of 2800 - 3200 HV. In contrast, CBN has a hardness of approximately 4500 - 5000 HV. This higher hardness gives ceramic - bonded CBN wheels a distinct advantage in terms of cutting ability. They can remove material more rapidly and efficiently, especially when dealing with hard and tough materials. For instance, when grinding hardened steel components, a ceramic - bonded CBN wheel can achieve a much higher material removal rate than an aluminum oxide or silicon carbide wheel, reducing the overall grinding time.

Wear Resistance

The wear resistance of ceramic - bonded CBN is far superior to that of conventional abrasives. The CBN grains are much more resistant to attrition, meaning they maintain their sharpness and shape for a longer time. Conventional abrasives tend to wear out quickly, especially when grinding hard materials, which leads to more frequent wheel replacements. A ceramic - bonded CBN wheel can last 50 - 100 times longer than a typical aluminum oxide wheel when grinding similar materials. This not only reduces the cost associated with wheel replacement but also minimizes downtime in production processes.

Grinding Precision

Ceramic - bonded CBN wheels offer exceptional grinding precision. The self - sharpening property of the ceramic bond, combined with the high hardness and wear resistance of CBN, allows for the creation of extremely smooth and accurate surfaces. In precision engineering applications, such as the grinding of aerospace components or medical devices, the ability to achieve tight tolerances and low surface roughness is crucial. Ceramic - bonded CBN wheels can consistently produce surface finishes with roughness values as low as Ra 0.2μm or even lower, far surpassing what can be achieved with conventional abrasives.

Why Choose Ruizuan's Vitrified - Bonded CBN Products

Advanced Manufacturing Technology: At Ruizuan, we utilize state - of - the - art manufacturing processes to produce our ceramic - bonded CBN products. Our facilities are equipped with the latest machinery and adhere to strict quality control measures, ensuring that each product meets the highest standards of performance.

Customization Options: We understand that different applications have unique requirements. That's why we offer a wide range of customization options for our ceramic - bonded CBN wheels, including variations in grain size, bond strength, and wheel geometry. Our team of experts works closely with customers to develop tailored solutions that optimize performance for their specific grinding tasks.

Technical Support: We provide comprehensive technical support to our customers. From initial product selection to on - site performance optimization, our team of engineers is available to offer guidance and assistance. We help customers choose the right ceramic - bonded CBN product for their application, recommend appropriate grinding parameters, and provide advice on wheel maintenance and dressing.

Vitrified - bonded CBN abrasives offer a host of advantages over diamond abrasives and conventional abrasives, particularly in the grinding of ferrous materials. Their superior chemical inertness, thermal stability, hardness, wear resistance, and grinding precision make them the ideal choice for a wide range of industrial applications. At Zhengzhou Ruizuan Diamond Tools, we are committed to providing our customers with the highest - quality ceramic - bonded CBN products and technical support to help them achieve optimal grinding results.

Copyright © Zhengzhou Ruizuan Diamond Tool Co.,Ltd. All Rights Reserved — Privacy Policy